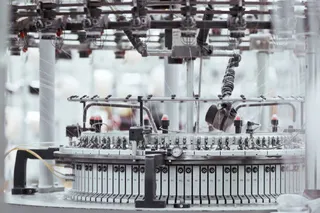

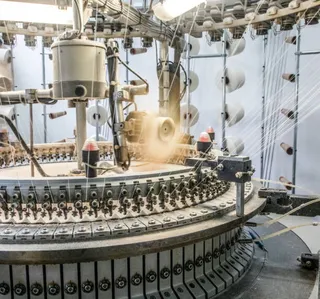

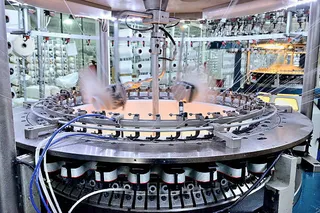

Circular Knitting Machine for Indonesia Market: Advanced Single Jersey Loop Pile Technology

Introduction As the demand for high-quality knitted fabrics continues to rise in the Indonesian textile market, circular knitting machines have emerged as essential tools for modern textile manufacturing. Among them, the Single Series Loop Pile Circular Knitting Machine stands out for its performance, flexibility, and versatility. Designed to meet the evolving needs of manufacturers across Indonesia, this machine offers a powerful combination of precision engineering and user-friendly operation,...