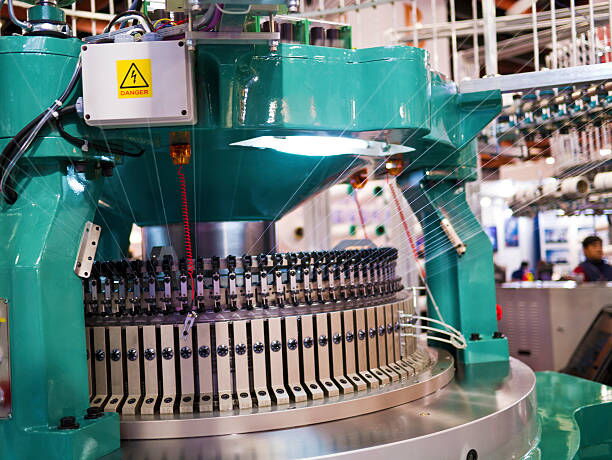

Circular Knitting Machine for Indonesia Market: Advanced Single Jersey Loop Pile Technology

Jun 06, 2025

As the demand for high-quality knitted fabrics continues to rise in the Indonesian textile market, circular knitting machines have emerged as essential tools for modern textile manufacturing. Among them, the Single Series Loop Pile Circular Knitting Machine stands out for its performance, flexibility, and versatility. Designed to meet the evolving needs of manufacturers across Indonesia, this machine offers a powerful combination of precision engineering and user-friendly operation, making it ideal for producing soft, durable fabrics such as towels, blankets, and looped pile textiles.

This article explores the technical features, advantages, and market potential of this cutting-edge circular knitting machine tailored for the Indonesian textile industry.

Specifications:

Diameter: 6 to 44 inches

Gauge: 14 - 44 gauge

Number of Feeders:

18F to 132F (3 feeders/inch)

24F to 176F (4 feeders/inch)

Applicable Yarn Types:

Pure cotton

Chemical fiber

Mixed fiber

Silk

Artificial wool

This wide range of specifications ensures the machine can handle diverse production requirements, from lightweight, breathable fabrics to heavier, more textured materials.

The machine’s core lies in its advanced 4-track cams design, which integrates knit cams, tuck cams, and miss cams to provide maximum versatility. This system supports complex fabric structures and enhances operational efficiency, offering a seamless transition between various knitting functions.

A hallmark of precision engineering, the central raising and falling system allows for quick and smooth adjustments in fabric density and weight. Operators can easily modify settings to suit different fabric styles without interrupting the production flow—boosting both productivity and consistency in output.

A specially designed feeding yarn carrier enables proficient Lycra integration. Additionally, the machine includes an intermediate yarn transfer ring, improving the accessibility and efficiency of yarn handling. This ergonomic innovation keeps yarn transfer smooth and stable during high-speed operations and prevents contact between the operator and moving machine parts—ensuring comfort and safety.

With replaceable heart parts, this knitting machine is not limited to a single function. It can be easily converted into a 3-thread fleece machine, terry machine, or other variants depending on the production needs. This flexibility allows manufacturers to diversify their product lines using a single machine base, reducing capital costs and expanding production capabilities.

Cities like Bandung, Jakarta, and Surabaya—known for their strong textile manufacturing presence—are ideal locations for deploying these circular knitting machines. With demand growing in local and export markets, textile mills can benefit from enhanced fabric quality, improved production speed, and lower operational costs.

The machine’s wide gauge and diameter options support tailor-made orders for fashion, home textiles, and specialty fabrics. Indonesian manufacturers looking to serve niche markets such as custom loop pile mats, sportswear linings, or luxury terry towels can capitalize on the machine’s flexibility.

Indonesia's textile exports remain strong, especially to regions like the Middle East, Europe, and the United States. The Single Series Circular Knitting Machine provides a high-capacity solution that maintains export-level fabric standards, enabling local businesses to compete globally with consistent quality and reduced downtime.

With high feeder counts (up to 176 feeders) and compatibility with a broad range of yarns, the machine ensures continuous, high-speed operation—translating to more output in less time.

From delicate silk to sturdy chemical fibers, the machine can accommodate the full spectrum of textile materials, allowing greater creativity and diversification in product development.

The ergonomic structure reduces physical strain and simplifies yarn handling, making the production environment safer and more comfortable for long shifts.

Thanks to its multipurpose nature, this machine minimizes the need for additional equipment, conserving factory space and reducing maintenance and investment costs.

The central adjustment system simplifies the process of changing fabric density, enabling faster transitions between product types—vital for small-batch and custom orders.

Indonesia’s textile sector is rapidly modernizing. As local manufacturers adopt smart technology and automation to stay competitive, investing in machines like the Single Jersey Circular Knitting Machine aligns with broader industrial trends. The government’s push for industry 4.0 adoption also encourages automation and digitization in textile production—further positioning this machine as an ideal addition to the modern factory floor.

In today’s environmentally conscious market, textile machinery must not only deliver high output but also align with sustainability goals. The efficient design of this machine ensures minimal yarn wastage, reduced energy consumption, and consistent quality—all of which contribute to lower environmental impact. Its ability to work with sustainable yarns like recycled polyester or organic cotton further enhances its green credentials.

Suppliers catering to the Indonesian market offer comprehensive after-sales support, including on-site installation, operator training, and periodic maintenance services. This ensures smooth adoption and minimal disruptions during operation. Technical teams are typically fluent in Bahasa Indonesia or provide interpreters, ensuring clear communication and effective problem-solving.

The Single Series Loop Pile Circular Knitting Machine is more than just a high-performance textile machine—it's a future-ready solution designed for flexibility, productivity, and adaptability. Tailored for the needs of the Indonesian market, it empowers textile manufacturers to improve quality, meet global standards, and reduce operational costs, all while keeping workers safe and production lines efficient.

Whether you're looking to scale your operations, improve production speed, or diversify your fabric offerings, this advanced circular knitting machine offers a competitive edge. With its modular functionality, ergonomic design, and wide material compatibility, it’s poised to be a game-changer in Indonesia’s growing textile industry.

Next: Three-Thread Fleece Circular Knitting Machine: Boosting Efficiency and Flexibility

Previous: Infrared Real-Time Yarn Monitoring in Circular Knitting Machines

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.