Understanding the Pulling-Up Device and Presser Foot in Circular Knitting Machines

May 26, 2025

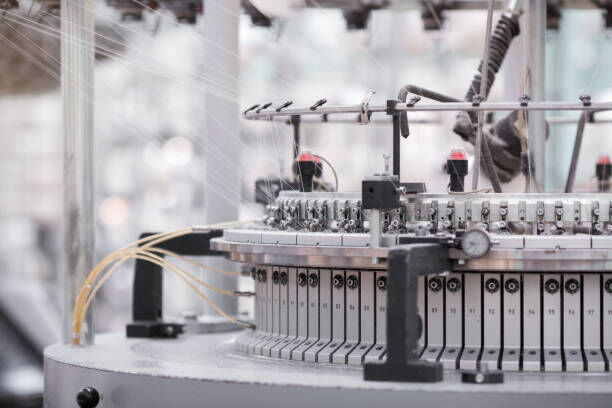

In the realm of textile manufacturing, circular knitting machines stand out as essential equipment for producing high-quality knitted fabrics. These machines, known for their efficiency and precision, rely on a combination of intricate mechanisms to ensure flawless performance. Among the key components that enable smooth operation are the knitting machine pulling-up device—often referred to as the rolling machine—and the presser foot assembly. While often overlooked, these components play critical roles in maintaining knitting consistency, protecting the longevity of machine parts, and enhancing production flexibility.

This article delves into the functions, classifications, and importance of the pulling-up device and presser foot, shedding light on how these mechanisms work in harmony to support continuous, high-quality knitting.

The pulling-up device is integral to the overall functionality of circular knitting machines. Its primary function is to manage the winding and tension of the fabric as it is formed and guided away from the knitting zone. By maintaining consistent tension and controlling fabric draw-off, the device ensures both the quality of the knitted product and the smooth operation of the machine.

Maintaining even pulling tension is fundamental in knitting operations. The pulling-up device exerts a controlled force that optimizes the stress placed on the needles. By doing so, it not only prevents the needles from wearing out prematurely but also ensures that the knitting process proceeds uniformly. This is vital for maintaining consistent stitch formation and fabric appearance throughout production.

A crucial feature of the device is its ability to synchronize the pulling speed with the knitting speed. Without this synchronization, issues such as fabric distortion, loop irregularities, or uneven knitting may occur. By ensuring that both speeds are matched, the device promotes harmonious interaction between the knitting head and the fabric take-up section, leading to efficient and reliable operation.

The pulling-up device also plays a pivotal role in controlling the maximum winding length of the fabric. This functionality is especially important for meeting specific production requirements. Whether producing rolls of varying sizes or working with different fabric types, the ability to adjust winding length provides manufacturers with much-needed operational flexibility.

Pulling-up devices can be classified into two primary types: Constant Torque Electric Traction Systems and Mechanical Stretch Cloth Systems. Each of these configurations offers unique advantages and is selected based on specific operational requirements.

This modern system employs stepless electronic control constant torque motors to regulate fabric winding. Its advanced design offers a number of benefits:

Unlike mechanical systems that rely on gear changes, the constant torque system delivers a steady torque output regardless of the load. This results in precise and smooth operation, which is essential for high-quality knitting.

These motors provide a linear response to control signals, meaning the output changes smoothly and predictably with adjustments. This ensures that the pulling force remains consistent across all stages of the process.

With minimal torque fluctuation, the system maintains fabric tension without abrupt changes, avoiding potential disruptions to the knitting rhythm.

The electric traction system is relatively simple in structure, facilitating ease of maintenance. Adjustments are fast and convenient, improving efficiency and reducing downtime.

Overall, constant torque systems are ideal for high-end or automated knitting operations where precision and adaptability are prioritized.

The mechanical pulling-up device relies on traditional gear mechanisms to regulate fabric tension. It functions by pulling the fabric through gear-driven rollers, with tension adjustments made via gear changes.

One of the primary advantages of this system is its cost-effectiveness. Mechanical devices are less expensive to produce and maintain, making them suitable for smaller operations or basic knitting applications.

Unlike the electric system, speed and tension adjustments are achieved by manually changing gears, which can interrupt production and requires operator expertise.

Mechanical systems tend to have more components and moving parts, making them slightly more complex to maintain and potentially more prone to mechanical wear over time.

Despite these limitations, mechanical systems are still widely used due to their affordability and proven reliability in specific knitting setups.

While the pulling-up device governs fabric tension and draw-off, the presser foot is responsible for controlling the material directly at the point of knitting. Attached to the presser foot bar, this component is crucial for guiding the material, applying appropriate pressure, and ensuring that the fabric is correctly positioned during the knitting process.

Presser feet used in circular knitting machines are generally categorized into:

Suitable for standard applications, the single presser foot provides basic control and pressure application for uniform fabrics.

For more complex or multi-layered materials, the double presser foot offers enhanced control. This configuration ensures that both upper and lower fabric layers are evenly managed, resulting in more stable and accurate knitting.

In certain applications, fabric guides or folders may also be installed alongside the presser foot. These accessories help manage fabric flow and alignment, especially for intricate seaming or decorative stitching.

Most presser feet are equipped with a spring-loaded mechanism that allows the operator to adjust the applied pressure. This adaptability is essential for accommodating different fabric types, from lightweight knits to thicker or stretchable materials.

The presser foot ensures that the fabric remains flat and in place while passing through the needles. By holding the material steady, it helps maintain accurate loop formation and prevents issues like puckering or shifting during knitting.

Beyond its functional role in knitting, the presser foot greatly assists in tasks such as seaming, tape binding, edge piping, and other precision applications. Operators rely on the presser foot to maintain fabric alignment and execute fine details with confidence and consistency.

In the event of damage or wear, presser feet are readily available in the market and can be replaced quickly. Proper adjustment and regular inspection of the presser foot are essential to ensure uninterrupted production and to uphold fabric quality.

The interplay between the pulling-up device and the presser foot is crucial for successful circular knitting. While one manages fabric tension and winding, the other handles material positioning and control. Together, they enable:

Consistent tension from the pulling-up device, combined with firm pressure from the presser foot, ensures uninterrupted fabric movement from the knitting zone to the take-up section.

With balanced control over fabric tension and material placement, both components contribute to uniform stitch formation, reducing errors and improving fabric aesthetics.

By minimizing stress on needles and fabric, these components extend the service life of machine parts and reduce the risk of downtime due to maintenance.

To maintain optimal performance of the pulling-up device and presser foot, manufacturers and operators should observe the following best practices:

Check for signs of wear, misalignment, or mechanical failure in both the pulling-up device and the presser foot assembly.

Keep moving parts well-lubricated and free of lint, dust, or fabric debris to prevent mechanical jamming and ensure smooth motion.

Periodically calibrate tension settings and presser foot pressure according to fabric type and production requirements.

Ensure that operators are trained in the correct usage, adjustment, and maintenance of these components to minimize human error and optimize output.

In the highly specialized world of circular knitting, attention to detail is everything. Components like the pulling-up device and the presser foot, though often overshadowed by more prominent parts like the knitting cylinder or needle bed, are vital to the consistent and high-quality production of knitted fabrics.

By understanding their roles, capabilities, and proper maintenance, manufacturers can not only extend the lifespan of their knitting machines but also enhance productivity and fabric quality. Whether opting for an advanced constant torque electric system or a traditional mechanical setup, and whether using single or double presser feet, investing in these components ensures a smooth, reliable, and efficient knitting operation.

As the textile industry continues to evolve, the importance of these small yet powerful devices will remain central to innovation and production excellence.

Next: Revolutionizing Textile Production with Double Jersey Knitting Machines

Previous: Understanding and Resolving Weft-Direction Streaks in Circular Knitting Machines After Stoppage

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.