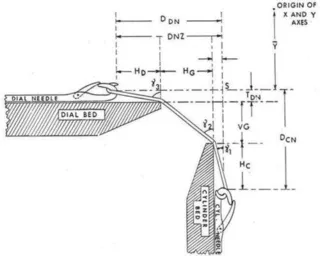

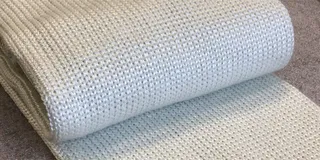

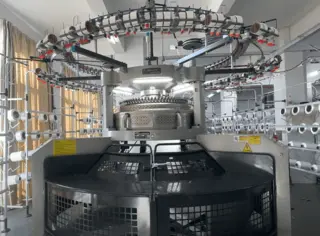

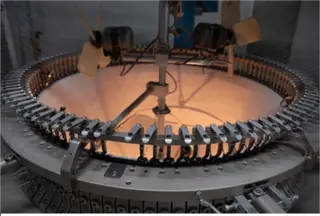

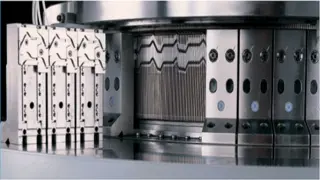

Position and Function of Settling Plate on Single Jersey Knitting Machine

In modern knitting technology, the settling plate an important part of knitting machine, its unique design and structure not only ensure the smooth formation and closure of the coil, but also affect the quality and production efficiency of the fabric. In this paper, the motion principle, design characteristics and the importance of settling plate in the knitting process of single jersey circular knitting machine are discussed in depth, and theoretical support and practical suggestions are provided...