Which Circular Knitting Machines Are Ideal for Double Knit Fabrics?

Sep 26, 2025

In the textile industry, double knit fabrics occupy a significant place due to their unique structure, durability, and versatile applications. Unlike single-layer knits, double knit fabrics are composed of two interlocked layers of fabric. This dual-layer construction provides enhanced stability, thickness, and dimensional strength, making double knits highly desirable for both fashion and technical applications.

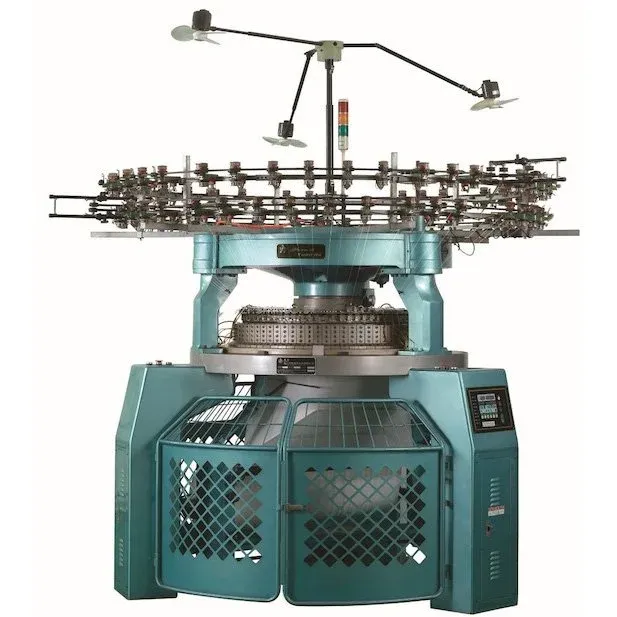

Producing high-quality double knit fabric requires specialized machinery, particularly circular knitting machines equipped to handle the complexities of double-layer construction. In this article, we delve into the types of circular knitting machines used to manufacture double knit fabrics, explore the varieties of double knit fabrics, and discuss their unique features and applications.

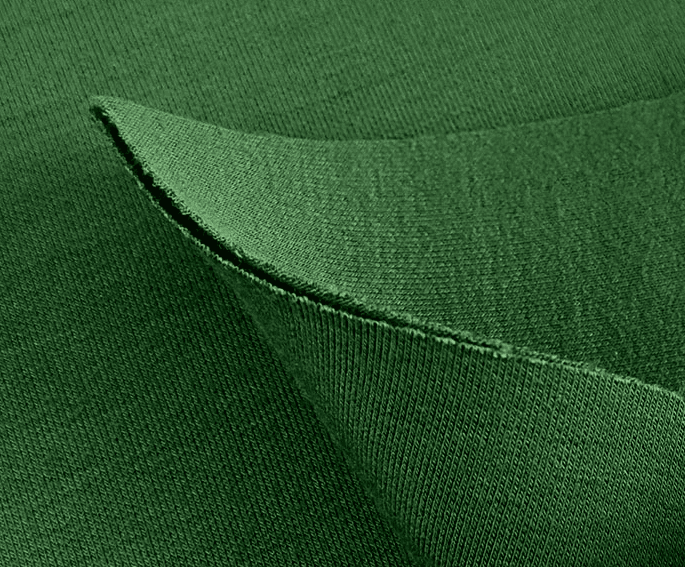

Double knit fabric is a type of knit fabric characterized by two layers of interlocked stitches. The two layers are created simultaneously, using techniques that bind them together, forming a single stable structure. This interlocking prevents the layers from separating or curling at the edges—a common issue with single-knit fabrics.

The result is a dense, firm textile with twice the thickness of a standard knit fabric. Double knits exhibit excellent dimensional stability, resist wrinkling, and maintain their shape even after multiple washes. This makes them particularly suitable for applications requiring durability, structure, and elasticity.

From a construction standpoint, double knit fabrics are made using circular knitting machines fitted with two needle beds. These machines can handle interlock, rib, or jacquard patterns, depending on whether the goal is elasticity, stability, or decorative complexity.

Circular knitting machines are the backbone of double knit fabric production. Unlike flatbed machines, circular knitting machines produce seamless tubular fabrics. For double knits, machines are equipped with two needle beds, allowing simultaneous formation of two interlocking layers of fabric. Let’s explore the main types used in the industry:

The interlock circular knitting machine is designed with two opposing needle beds, each containing a cylinder and dial needle configuration. These machines produce interlock fabrics—a type of double knit known for its thickness, stability, and dimensional strength.

Characteristics:

Smooth, uniform surface on both sides

Dense and firm structure

Excellent resistance to curling

High durability

Applications: Interlock fabrics are widely used in sportswear, underwear, outerwear, and premium apparel where stability, stretch, and comfort are essential.

Rib circular knitting machines are equipped with two sets of needles arranged at right angles, enabling the creation of ribbed fabrics. These fabrics can be 1x1, 2x2, or other rib variations, offering stretchability while maintaining shape retention.

Characteristics:

High elasticity

Reversible appearance

Form-fitting yet flexible

Applications: Rib fabrics are commonly used for cuffs, collars, waistbands, and body-hugging garments, providing both comfort and stretch.

For patterned double knit fabrics, the double jersey jacquard circular knitting machine is ideal. These machines are often computer-controlled, allowing precise needle selection to produce complex multicolor or textured patterns.

Characteristics:

Can produce single- or double-sided patterns

Supports intricate designs and textures

High precision and versatility

Applications: Double jersey jacquard fabrics are suitable for fashion garments, decorative textiles, and professional projects requiring visually appealing and structurally stable fabrics. Modern machines, such as YUANDA computerized jacquard circular knitting machines, enable advanced customization, combining efficiency with creative freedom.

Double knit fabrics are diverse, with each type having distinct characteristics and applications. Understanding the differences is crucial for selecting the right fabric for specific end uses. Below are some commonly produced double knit fabrics:

Double pique fabric, sometimes simply called double knit pique, is characterized by a slightly raised or ribbed surface, providing a soft texture and breathable feel. The double-layer construction enhances durability and moisture-wicking properties, making it suitable for activewear and casual clothing.

Features:

Soft and textured surface

Breathable and moisture-wicking

Durable and stable

Applications: Polo shirts, sportswear, and casual apparel benefit from the comfort and structure of double pique fabric.

Double jersey fabrics are produced using two sets of yarn and two needle beds. This double construction results in fine longitudinal ribs on both sides, creating a dense, smooth, and stable fabric. Unlike single jersey fabrics, which are prone to curling, double jersey fabrics maintain shape and drape well.

Features:

Fine ribs on both sides

Dense and stable construction

Smooth texture with minimal curling

Applications: Heavy-duty garments such as hoodies, jackets, upscale T-shirts, and baby layette items commonly use double jersey fabrics for their durability and comfort.

Scuba knit is a smooth, double-knit fabric made from polyester and spandex, resembling thin neoprene. Known for its excellent stretch and recovery, scuba fabric drapes well and gives structure to garments, often featuring a subtle sheen.

Features:

Excellent stretch and recovery

Smooth texture with low-luster shine

Full-bodied drape

Applications: Fashionable outerwear, structured dresses, and activewear often employ scuba fabric due to its flexibility, durability, and modern appearance.

Double jacquard fabrics are designed for intricate patterns and multicolor designs. Produced using computerized jacquard circular knitting machines, these fabrics can be double-sided, providing versatility and elasticity. Knitted jacquard fabrics are more drapable and breathable than woven alternatives, making them suitable for premium garments.

Features:

Complex, multicolored patterns

Elastic, breathable, and drapable

Double-sided design

Applications: Luxury apparel, decorative textiles, and professional projects benefit from double jacquard fabrics for their aesthetic appeal and functional properties.

Interlock knit fabric is a smooth, double-sided ribbed fabric formed by interlacing two rows of stitches. Unlike standard knit fabrics that show knit and purl ridges, interlock knit fabric is soft, uniform, and reversible. It can be knitted with various fibers, including cotton and polyester.

Features:

Soft, smooth texture

Double-sided, reversible

Stable and firm

Applications: Interlock fabrics are ideal for T-shirts, sportswear, children’s clothing, and casual wear where softness, stability, and comfort are key.

Liverpool knit fabric is a heavier and less elastic type of double knit compared to standard double knits. Known for its exceptional 4-way stretch and resistance to sun fading, it maintains its shape and elasticity over time.

Features:

Durable and long-lasting

Excellent 4-way stretch

Resistant to sun fading

Smooth surface with elegant drape

Applications:

Ideal for shirts, skirts, dresses, loosely fitted jackets, and other apparel that requires both structure and flexibility.

Rib knit fabric features vertical textured lines created using two needles, alternating knit and purl stitches across the width of the fabric. This design provides flexibility, a pleasant texture, and versatile functionality.

Features:

Soft and elastic

Comfortable against the skin

Durable and flexible

Distinct vertical ribbed texture

Applications:

Perfect for clothing cuffs, neckbands, trims, as well as dresses, shirts, pyjamas, and other garments needing stretch and comfort.

Double knit fabrics offer numerous benefits over single knits and woven textiles, making them widely adopted in fashion, sports, and technical apparel:

Stability: Double knit fabrics resist curling at the edges and maintain their shape even after multiple washes.

Thickness and Warmth: With two interlocked layers, double knits provide additional insulation, making them suitable for winter apparel and outerwear.

Durability: The double construction enhances tensile strength and resistance to wear and tear.

Elasticity and Comfort: Depending on the type (rib, interlock, or jacquard), double knits offer varying degrees of stretch while maintaining structural integrity.

Aesthetic Appeal: Jacquard and textured double knits allow designers to create visually appealing garments with patterns and colors on both sides.

These advantages explain why double knits are preferred for garments that require a combination of style, durability, and comfort.

Double knit fabrics are highly versatile and find applications across a wide range of industries:

Fashion and Apparel: Jackets, hoodies, skirts, dresses, activewear, T-shirts, and children’s clothing often employ double knit fabrics for their structure and comfort.

Sportswear: Interlock and rib fabrics provide elasticity and support, making them ideal for activewear and athletic apparel.

Outerwear: Scuba and double jersey fabrics offer insulation and durability, making them suitable for coats and jackets.

Home Textiles: Double pique and jacquard fabrics are used in blankets, cushion covers, and upholstery for their texture, stability, and aesthetic appeal.

Technical Textiles: Specialized double knit fabrics are applied in automotive interiors, medical textiles, and protective clothing, leveraging their strength, stability, and comfort.

The evolution of circular knitting machines has greatly enhanced the production of double knit fabrics. Modern machines, especially computerized jacquard circular knitting machines, allow precise needle selection and automation, reducing labor costs and improving design complexity.

Advancements in yarn technology also complement machine capabilities. Blended fibers like polyester-spandex or cotton-polyester offer stretch, recovery, and moisture management, expanding the functional scope of double knits.

Sustainability is another focus area. Many manufacturers are adopting eco-friendly yarns and energy-efficient circular knitting machines to minimize environmental impact, producing high-quality double knit fabrics with reduced carbon footprints.

Double knit fabrics are a cornerstone of modern textile manufacturing, providing a unique combination of durability, elasticity, and aesthetic versatility. Their production requires specialized circular knitting machines, including interlock, rib, and jacquard variants, each suited for specific fabric characteristics and applications.

From soft and breathable double pique fabrics to structured scuba knits and intricately patterned double jacquard fabrics, double knits cater to a wide spectrum of needs across fashion, sportswear, technical textiles, and home textiles. Innovations in machine technology, yarn blends, and sustainable manufacturing practices continue to expand the possibilities of double knit fabrics, ensuring they remain a preferred choice for high-quality, versatile textiles.

For manufacturers and designers alike, understanding the types of circular knitting machines and the characteristics of double knit fabrics is essential for achieving the desired balance of comfort, functionality, and visual appeal in their products.

Next: Essential Maintenance Tips for Beginners Using Circular Knitting Machines

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.