Advanced Double Jersey Pique Fabric Circular Knitting Machine Introduced for Ethiopia’s Textile Industry

Sep 22, 2025

The Ethiopian textile and garment sector has been gaining international attention for its rapid growth, competitive workforce, and strong government backing. With the country positioning itself as a global sourcing destination, the need for advanced textile machinery has never been greater. Among the many technological innovations entering the Ethiopian market, the Double Jersey Pique Fabric Circular Knitting Machine stands out as a game changer.

This machine represents the epitome of textile craftsmanship — a blend of engineering precision, cutting-edge innovation, and operational efficiency. Designed to produce premium-quality double jersey pique fabrics, it empowers Ethiopian manufacturers to compete at the global level while supporting the domestic industry’s ambition of becoming a sustainable, high-value textile hub.

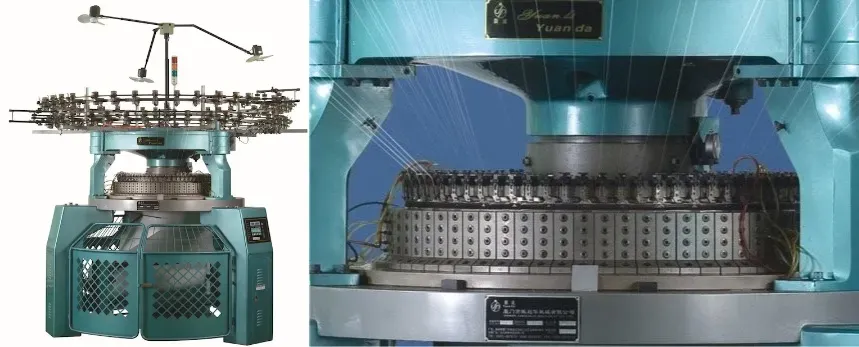

The PC Double Jersey Pique Fabric Circular Knitting Machine is built to meet the diverse demands of modern fabric production. Its flexible configuration allows it to cater to multiple applications, from high-fashion apparel to functional fabrics.

Product: PC Double Jersey Pique Fabric Circular Knitting Machine

Diameter: 8 – 44 inches

Gauge: 6 – 40 gauge

Feeder Quantity: 16 to 88/106 feeders

Available Materials: Interlock fabrics, elastic health cloth, twill, air layer, double mesh, men’s and women’s apparel, and more

Closed-Track Cam System: Installed on both upper and lower dials, supporting knit, tuck, and miss functions for enhanced pattern diversity.

Independent Yarn Feeder Control: Each yarn feeder can be adjusted independently, ensuring precision and flexibility.

Lycra Attachment: With an additional component, the machine can knit elastic double jersey fabrics, ideal for sportswear and performance textiles.

Interchangeable System: Can be converted into rib knitting machines, reducing capital investment for factories that need flexibility.

Stable Performance: Designed for consistency and high productivity, making it a favored model among textile manufacturers worldwide.

Prevents vibration during operation, even at high speeds.

Enables smooth transitions between knit, tuck, and miss functions, offering creative freedom for fabric designers.

Whether producing pique fabrics, twills, or double mesh, the machine handles multiple fabric types with ease.

Its modular design reduces the need for multiple machines.

Uniformity of stitches across the fabric ensures consistent quality, essential for meeting international standards.

Optimized drive systems reduce electricity consumption, lowering operational costs — a major benefit for Ethiopian factories seeking to maximize margins.

Constructed with robust materials, it withstands continuous use, ensuring long-term returns on investment.

Over the past decade, Ethiopia has emerged as a leading textile and apparel hub in Africa. The government has made the sector a national priority, offering incentives for investors, establishing industrial parks, and investing in infrastructure.

Key strengths driving Ethiopia’s textile growth:

Labor Advantage: A large, young, and trainable workforce at competitive wage levels.

Policy Support: Tax incentives, customs benefits, and investment-friendly regulations.

Trade Agreements: Duty-free access to markets such as the United States under AGOA and to Europe under the Everything But Arms (EBA) initiative.

Raw Materials: Abundant availability of cotton, coupled with growing interest in synthetic and blended fabrics.

Yet, while labor and resources are abundant, the industry’s long-term competitiveness hinges on advanced technology. Machines like the Double Jersey Circular Knitting Machine play a critical role in bridging the gap between resource potential and high-value textile production.

The fabrics produced by this machine are versatile, durable, and highly valued across multiple sectors:

Elastic, breathable fabrics for T-shirts, polo shirts, and performance gear are among the fastest-growing global segments. Ethiopia, with its growing manufacturing base, can tap into this demand.

Double jersey pique fabrics are widely used in everyday clothing, including men’s and women’s fashion. Interlock and twill fabrics add diversity for high-end apparel.

Elastic health cloth supports medical wear and functional clothing, an area gaining importance after the global pandemic.

Fabrics like double mesh and air layer provide applications in furniture, bedding, and home décor — sectors with significant export potential.

By producing these fabrics locally, Ethiopia reduces reliance on imports and increases value addition in its textile supply chain.

International buyers require fabrics that meet stringent quality standards. The Double Jersey Circular Knitting Machine ensures Ethiopian textiles can compete with those from China, India, and Turkey.

The interchangeable design reduces capital investment and maintenance costs. For emerging economies like Ethiopia, this makes production more accessible.

With one machine producing fabrics suitable for fashion, sportswear, and industrial use, Ethiopian factories can serve multiple market segments simultaneously.

By offering high-quality pique and double jersey fabrics, Ethiopia can position itself as a reliable supplier to Europe, the U.S., and Asia.

Multiple feeders enable large-scale output while maintaining precision.

Modular parts and simplified design make servicing straightforward, reducing downtime.

Independent yarn feeder adjustments make it easier for workers to manage, lowering skill barriers.

Available in a wide range of diameters and gauges, it can be tailored to specific production needs.

Adds elasticity to fabrics, allowing Ethiopian factories to produce advanced performance wear.

Ethiopia has set its sights on becoming a leading textile exporter in Africa by 2030. The adoption of advanced machinery is key to this vision. The Double Jersey Circular Knitting Machine supports this journey in several ways:

With high-quality fabrics, Ethiopia can secure long-term contracts with international retailers.

By moving from raw cotton exports to finished fabric production, Ethiopia captures more value domestically.

Operating and maintaining advanced machines requires skilled labor, supporting workforce development.

Local manufacturers can experiment with new fabrics and designs, stimulating creativity and product diversification.

The global textile industry is shifting toward sustainability, customization, and speed-to-market. Ethiopia is uniquely positioned to capitalize on these trends:

Sustainability: With abundant renewable energy resources, Ethiopia can market itself as a green textile hub. Machines with energy-efficient designs, like this circular knitting machine, align with this narrative.

Customization: Global buyers want flexibility. The machine’s ability to produce diverse fabrics meets these demands.

Nearshoring: Brands are diversifying sourcing beyond Asia. Ethiopia offers a strategic location close to European and Middle Eastern markets.

Investing in Double Jersey Circular Knitting Machines offers Ethiopian textile factories:

Higher Margins through production of premium fabrics.

Reduced Risk with flexibility across product lines.

Future-Proof Operations by aligning with global sustainability and fashion trends.

For international investors setting up in Ethiopia’s industrial parks, adopting such advanced machines ensures immediate competitiveness.

By 2030, Ethiopia could become one of Africa’s largest textile exporters. Achieving this requires balancing competitive labor costs with technological sophistication. The Double Jersey Pique Fabric Circular Knitting Machine provides the missing link: advanced technology that transforms Ethiopia’s resource advantage into a global competitive edge.

As more Ethiopian manufacturers adopt machines of this caliber, the country will not only increase its export revenues but also cement its reputation as a world-class textile hub.

The Double Jersey Pique Fabric Circular Knitting Machine is more than a piece of equipment — it is a strategic tool for Ethiopia’s textile industry. Combining precision, flexibility, and efficiency, it empowers manufacturers to produce world-class fabrics that meet international standards.

From sportswear and casual apparel to medical and home textiles, the fabrics created with this machine open doors to diverse markets. For Ethiopia, investing in such advanced technology means reducing dependence on imports, adding value locally, and capturing new export opportunities.

As Ethiopia advances toward its 2030 vision of becoming a global textile powerhouse, machines like this will stand at the center of its industrial progress — enabling not just production, but transformation.

Next: Which Circular Knitting Machines Are Ideal for Double Knit Fabrics?

Previous: Open Width Circular Knitting Machines: Transforming Textile Manufacturing

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.