Open Width Circular Knitting Machines: Transforming Textile Manufacturing

Sep 19, 2025

The textile industry is one of the world’s oldest yet most rapidly evolving sectors. From hand-operated looms to automated knitting and weaving systems, innovation has always been central to its progress. In recent years, the rising demand for faster production cycles, higher-quality fabrics, and sustainable practices has encouraged manufacturers to embrace more advanced machinery. Among these innovations, Open Width Circular Knitting Machines have become a pivotal development, reshaping how fabrics are produced and finished.

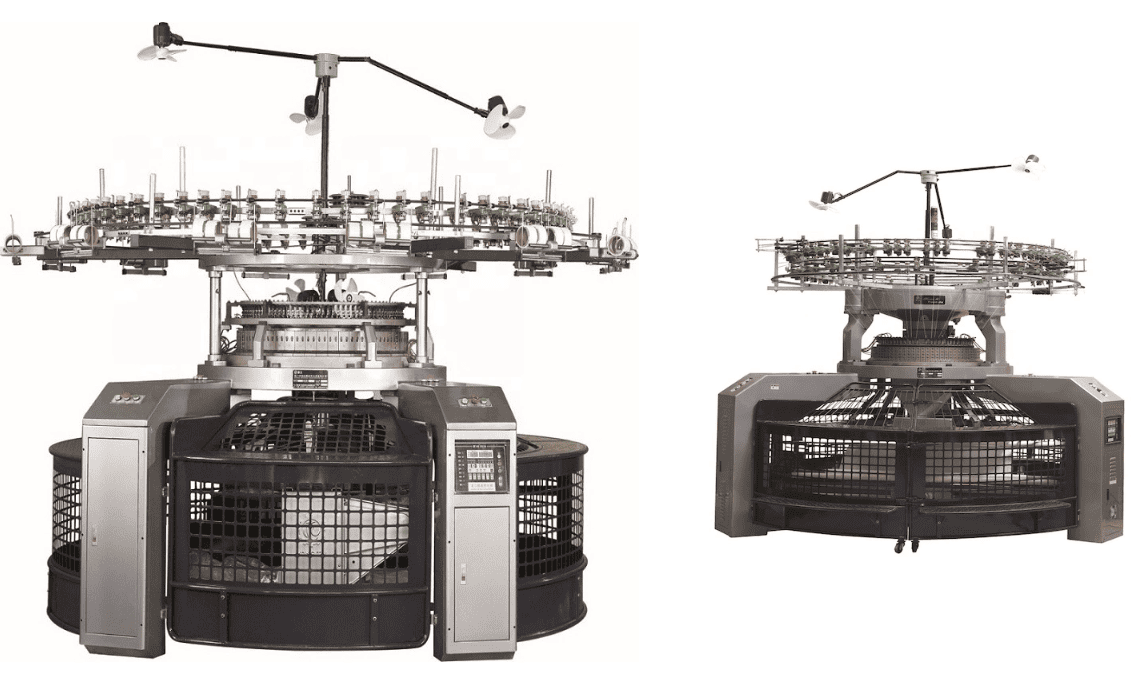

Unlike conventional circular knitting machines, which typically manufacture fabric in tubular form, open width circular knitting machines are designed to produce fabric in a flat, sheet-like format. This single but crucial difference has revolutionized textile manufacturing, unlocking improvements in efficiency, quality, versatility, and environmental sustainability. Today, these machines are not just an option but a necessity for textile companies seeking to remain competitive in global markets.

This in-depth article examines the evolution, features, applications, benefits, challenges, and future trends of open width circular knitting machines, demonstrating why they have become a cornerstone of modern textile manufacturing.

Circular knitting machines have been widely used since the early 20th century, with tubular machines dominating due to their simplicity and speed. However, the post-processing step of cutting tubular fabric into open width has always been a source of inefficiency. Manufacturers often faced challenges such as seam marks, uneven cutting, and waste material.

The introduction of open width circular knitting machines addressed these limitations by integrating mechanisms that allow fabric to be spread flat during production. This eliminated the need for slitting, which not only improved efficiency but also reduced waste and maintained fabric integrity. Over time, the machines have been enhanced with computer controls, electronic jacquards, and automatic take-down systems, making them more precise, versatile, and user-friendly.

The functionality of open width circular knitting machines is based on a combination of traditional knitting principles and advanced engineering innovations. While they share similarities with conventional tubular knitting machines, the addition of specialized mechanisms allows them to produce fabric in a flat, open width form, which is immediately ready for downstream processes.

At the heart of the machine is the knitting cylinder equipped with needles. Yarn is continuously fed into the rotating cylinder, where the needles interloop the yarn to create knitted fabric. This stage mirrors the operation of tubular machines, but what sets open width machines apart is what happens immediately after the knitting process.

Next comes the spreader mechanism, a unique feature designed to open and maintain the fabric in a flat form. Without this step, the fabric would naturally curl into a tubular shape due to the knitted structure. The spreader ensures that the fabric remains evenly stretched, minimizing distortions and preserving uniform width across the entire roll. This stage is crucial for achieving high-quality results and ensuring that the fabric can be efficiently processed in later steps such as printing, dyeing, or finishing.

Finally, the take-down system manages the downward movement of the fabric under controlled tension. By carefully regulating the pull on the material, this system prevents curling, puckering, or stretching that could compromise quality. Once stabilized, the fabric is wound directly onto rolls, making it easy to handle, transport, and feed into subsequent finishing equipment.

By integrating these three essential components—knitting cylinder and needles, spreader mechanism, and take-down system—open width circular knitting machines streamline the production cycle. They eliminate the need for additional steps such as slitting tubular fabrics, which saves both time and raw materials. The result is a fabric that is more consistent, easier to process, and immediately ready for large-scale textile applications.

These machines can produce fabrics of varying widths and weights, making them suitable for applications ranging from lightweight t-shirts to heavy upholstery textiles.

Since the fabric exits the machine in open width form, it can be immediately processed. Dyeing, printing, and finishing operations are smoother and faster, reducing production bottlenecks.

The flat production format minimizes spirality and side-seam marks often seen in cut tubular fabrics. This results in more uniform, consistent, and higher-quality fabrics.

Whether it is cotton, polyester, nylon, wool, viscose, or blended fibers, open width machines can adapt seamlessly. This flexibility allows manufacturers to diversify product lines.

Modern machines come with computerized interfaces that allow easy pattern programming, reducing dependency on skilled manual labor while enabling complex designs.

By avoiding slitting, manufacturers reduce fabric waste and optimize material use. Moreover, newer machines feature energy-efficient motors, helping lower environmental impact.

|

Feature |

Tubular Machines |

Open Width Machines |

|

Fabric Format |

Tubular |

Flat (open width) |

|

Post-Processing |

Requires slitting |

Ready for finishing |

|

Waste Levels |

Higher (due to cutting) |

Lower |

|

Quality Issues |

Spirality, seam marks |

Minimal defects |

|

Speed |

High |

Slightly lower but more efficient overall |

|

Flexibility |

Limited widths |

Wide range of widths |

While tubular machines still dominate in certain low-cost applications, open width machines are rapidly becoming the preferred option for high-quality, efficient, and sustainable production.

The adaptability of open width knitting technology has opened opportunities across multiple industries:

Ideal for producing t-shirts, dresses, skirts, leggings, sweaters, and outerwear.

The flat format simplifies cutting and pattern alignment in garment factories.

Fabrics requiring stretch, breathability, and durability are easily achieved.

Performance textiles such as quick-dry and moisture-wicking fabrics benefit greatly.

Wide-format fabrics are perfect for bed sheets, pillowcases, upholstery, and curtains.

Used in automotive seat covers, filtration materials, and protective textiles.

Production of bandages, sanitary materials, and hospital clothing is streamlined with the precision of open width machines.

Fashion Brands in Europe: Several fast-fashion companies have adopted open width machines to speed up production and meet rapid market turnover demands. By eliminating slitting, they reduced lead times by up to 15%.

Asian Sportswear Manufacturers: A large activewear supplier in China reported 10% material savings after switching from tubular to open width machines, directly improving profit margins.

Home Textile Producers in Turkey: Upholstery manufacturers adopted these machines to handle heavier fabrics and wider widths, expanding their product offerings to international markets.

These real-world examples demonstrate how open width knitting machines not only improve efficiency but also drive competitiveness in global markets.

The newest generation of open width circular knitting machines goes beyond traditional automation, embracing Industry 4.0 innovations:

IoT Connectivity: Machines can be connected to factory networks for real-time monitoring.

Predictive Maintenance: Sensors detect wear and alert operators before breakdowns occur.

AI-Driven Pattern Design: Some advanced models allow AI-assisted fabric design to optimize production.

Energy Optimization Software: Systems adjust motor output and consumption based on workload.

These innovations are transforming textile factories into smart, data-driven operations.

While open width circular knitting machines provide clear advantages in efficiency, quality, and sustainability, their adoption is not without challenges. One of the primary concerns for manufacturers is the higher initial investment. Compared to conventional tubular machines, open width models require a greater upfront cost due to their advanced technology, integrated controls, and precision engineering. For small or medium-sized factories, this investment can be a significant financial hurdle.

Another consideration is operator training. Modern machines are equipped with computerized interfaces, automatic controls, and digital programming functions. Operators accustomed to older systems must be trained to manage these advanced features, ensuring smooth operation and minimizing downtime. This learning curve may temporarily affect productivity until teams are fully skilled.

Maintenance and service requirements also play a role. The precision parts that deliver superior performance require regular inspection, lubrication, and timely replacement to avoid costly breakdowns. Factories need to plan for these expenses as part of ongoing operational costs.

Finally, competition within the textile sector continues to intensify. As more companies embrace open width technology, maintaining differentiation requires continuous innovation, whether in fabric design, product quality, or customer service.

Despite these challenges, most manufacturers find that the long-term benefits—higher efficiency, reduced waste, and better-quality fabrics—far outweigh the initial barriers.

Several factors are driving future growth:

Global fashion and textile industries are under pressure to reduce waste and emissions.

Open width knitting aligns perfectly with eco-conscious goals.

Demand for protective, medical, and automotive fabrics is growing, requiring precision manufacturing.

Integration of conductive yarns and wearable technology will require advanced machines capable of handling new materials.

Future machines will increasingly integrate artificial intelligence for pattern design, defect detection, and autonomous operation.

Countries in Asia, Africa, and South America are investing in textile infrastructure, with open width machines often at the center of modernization projects.

Open Width Circular Knitting Machines have evolved from niche equipment to industry essentials, offering unmatched advantages in flexibility, efficiency, quality, and sustainability. By eliminating the limitations of tubular fabric production, they enable manufacturers to streamline processes, reduce waste, and meet the rising global demand for high-quality and eco-friendly textiles.

As technology continues to advance and markets evolve, these machines are set to play an even greater role in shaping the future of textile manufacturing. For companies aiming to stay competitive in the fast-paced and environmentally conscious textile landscape, investing in open width circular knitting machines is not just a strategic choice—it is a necessity.

In short, open width circular knitting machines are far more than equipment: they are engines of innovation, sustainability, and growth for the textile industry of tomorrow.

Previous: Electronic Loop Cut Jacquard Circular Knitting Machine for Jordan Market

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.