Single Jersey Open Width Knitting Machine to Transform Colombia’s Textile Industry

Jul 28, 2025

The Colombian textile industry is stepping into a new era of innovation and productivity with the arrival of the Single Jersey Open Width Circular Knitting Machine—a revolutionary knitting system designed to elevate fabric quality, boost efficiency, and expand production versatility. This advanced machine, equipped with the latest textile engineering technologies, aims to meet the increasing demands of Colombia’s growing textile and apparel markets, renowned for their diversity ranging from everyday wear to specialized sports and technical textiles.

Knitting technology has long been a cornerstone of fabric production, and the development of circular knitting machines has enabled manufacturers to produce a wide variety of knitted fabrics with speed and consistency. However, traditional knitting machines often face challenges such as fabric creasing, uneven stitch density, and limited adaptability to different materials and styles. The Single Jersey Open Width Circular Knitting Machine addresses these challenges with an innovative design focused on improving fabric quality while reducing material waste and operational complexity.

At its core, the Single Jersey Open Width Circular Knitting Machine is engineered to produce single jersey knit fabrics with an open width winding system that ensures the fabric remains flat and crease-free throughout production. The open width finishing method is highly favored in the industry for its ability to preserve fabric appearance and prevent defects caused by traditional winding methods, which often result in fabric folds and tension inconsistencies.

The machine’s roller shifting device further enhances fabric handling by dynamically adjusting fabric tension and winding position. This sophisticated mechanism prevents fabric from developing creases or bar marks, ensuring an impeccable surface finish that is critical for high-end garment applications like swimwear, underwear, and sportswear.

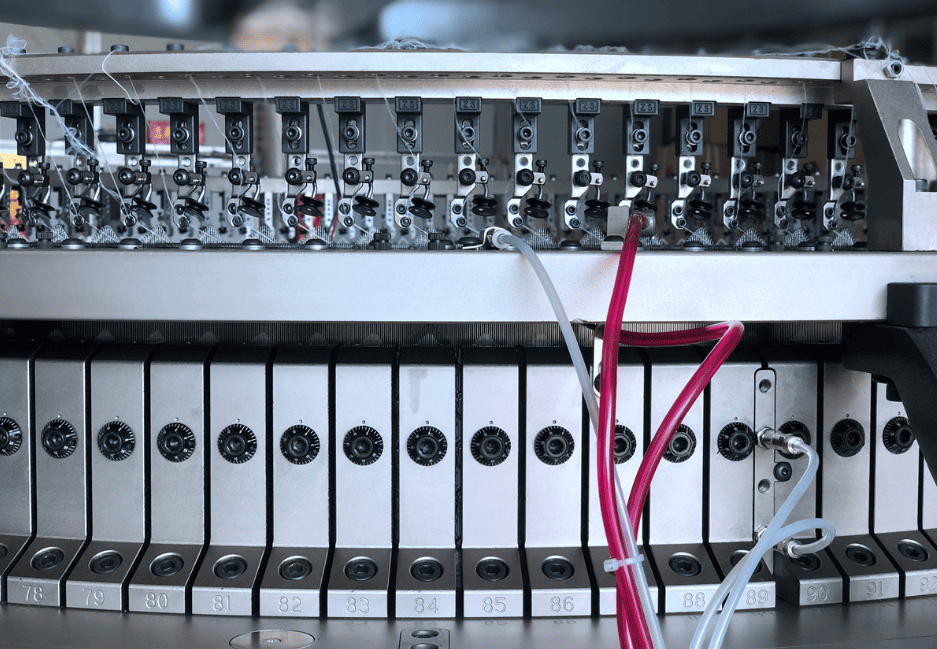

The machine is available in diameters ranging from 26 inches to 44 inches, catering to small and large-scale fabric production requirements. Its gauge range from 18 to 40 allows it to knit everything from relatively coarse, durable fabrics to fine, delicate textiles. The flexibility in feeder quantity—from 78 to 132 feeders or 104 to 176 feeders depending on the model—offers manufacturers the option to scale up their knitting speed and complexity as per their production goals.

This knitting machine supports a wide variety of yarn materials, including:

Cotton: Known for breathability and comfort, ideal for T-shirts and underwear.

Silk: Luxurious and smooth, perfect for high-end apparel.

Wool: Warm and insulating, suited for cold-weather sportswear and technical textiles.

Elastic fibers: Including spandex and other elastomers, essential for stretch fabrics used in gym suits, tights, and swimwear.

This versatility in yarn compatibility translates into a broad product range, such as:

Swimwear

Tights and hosiery

Underwear and lingerie

T-shirts and polo shirts

Gym and sportswear

Technical textiles for industrial applications

The quality of a knitting machine lies in its component engineering, and this machine excels in that aspect. All parts and accessories are manufactured using advanced machining centers to ensure tight tolerances and perfect fit. This precision manufacturing results in longer machine life, consistent fabric quality, and reduced downtime for maintenance.

One standout feature is the cam system, a vital component controlling the needles' movement. The cams undergo a special imported heat treatment process that significantly enhances hardness and wear resistance. This means the machine can sustain high production speeds without compromising needle precision or fabric quality.

Furthermore, the machine’s mainframe components are positioned using CAD/CAM technology to ensure exact needle track alignment. Such meticulous positioning guarantees smooth needle action and consistent stitch formation, which is critical when working with different materials and complex textile structures.

Unlike conventional machines, this system winds the fabric in an open flat form, avoiding folding or creasing. The roller shifting device adjusts fabric positioning during winding to maintain uniform stitch density across the entire fabric width. This system maximizes fabric utilization, minimizing waste and ensuring each meter of fabric meets strict quality standards.

The machine features a dual track drive system with specially designed tracks that reduce friction and wear on mechanical parts. This system results in smoother operation, less noise, and fewer mechanical defects like bar marks on the fabric. It also extends the lifespan of key components, lowering maintenance costs.

The machine offers multiple needle track arrangements, with the four-track needle configuration being the most popular. This flexibility enables the production of innovative and diverse knit patterns. By adjusting needle and sinker positions, manufacturers can create fabrics with varied textures, weights, and elasticity.

This design innovation allows for precise adjustment of fabric weight and density. The sinker triangle controls how the yarn is manipulated during knitting, affecting fabric thickness and stretchability. The closed design ensures the fabric's stability and uniformity, critical for performance wear and fashion textiles.

Adding elastic fibers like spandex has traditionally been challenging, but the machine’s specially designed feeders simplify this process. The transition feeder rings facilitate smooth yarn feeding, enabling high-speed weaving of complex fabric blends with spandex and other stretch fibers, which are essential in sportswear and activewear.

The Single Jersey Open Width Circular Knitting Machine is designed for easy operation and maintenance. Operators benefit from a user-friendly interface that allows quick adjustment of settings to optimize fabric weight, gauge, and pattern. The machine’s modular design means critical components like the cylinder can be replaced swiftly, reducing downtime during product changeovers.

The fabric take-up system is engineered to roll the fabric smoothly without producing shadows or marks, preserving fabric quality. Moreover, the machine is equipped with a safety stop device that automatically halts production if fabric slitting is incomplete or abnormal tension is detected, protecting valuable material and preventing machine damage.

A key selling point of this knitting machine is its versatility. By simply changing the sinker triangle arrangements and core components, manufacturers can switch between producing:

Satin cotton fabrics

Polyester cover cotton blends

Striped fabrics

Sweatshirts

Towels

This adaptability allows textile producers to diversify their product lines using a single piece of equipment, maximizing return on investment and responding flexibly to market trends.

Colombia’s textile and apparel sector has shown steady growth, supported by increasing domestic demand and expanding export opportunities. The introduction of this advanced Single Jersey Open Width Circular Knitting Machine is poised to catalyze further growth by:

The machine’s technology ensures Colombian manufacturers can produce fabrics that meet international quality standards, crucial for export markets in North America, Europe, and Latin America.

With crease elimination and uniform stitch density, fabric wastage is minimized, improving cost-efficiency and sustainability.

Versatility in fabric production supports diversification into high-demand segments like sportswear, technical textiles, and fashion apparel.

High feeder counts and advanced feeding systems boost throughput, helping manufacturers meet tight deadlines and large orders.

User-friendly features and automation reduce manual intervention, allowing operators to focus on quality control and innovation.

Textile production is often scrutinized for environmental impact, especially water use and chemical treatments. The Single Jersey Open Width Circular Knitting Machine supports more sustainable production by:

Eliminating creases and folds that would otherwise require reprocessing or fabric rejection, thus reducing waste.

Reducing energy consumption due to its efficient drive and winding systems.

Allowing for the knitting of technical textiles that can be used in eco-friendly applications, such as moisture-wicking sportswear or medical textiles.

Economically, this machine helps Colombian manufacturers remain competitive against global players by reducing per-unit production costs and increasing product quality, leading to higher margins and greater market share.

The Single Jersey Open Width Circular Knitting Machine represents a leap forward in knitting technology tailored to meet the needs of the Colombian textile industry. Its innovative design, precision engineering, and versatile capabilities enable manufacturers to produce top-quality fabrics efficiently and sustainably.

As Colombia continues to strengthen its position in the global textile market, integrating cutting-edge equipment like this knitting machine will be essential. By embracing this advanced technology, Colombian textile producers can enhance their competitiveness, expand their product range, and contribute to a more sustainable industry.

This knitting machine is more than a tool—it’s a strategic asset that empowers manufacturers to meet evolving consumer demands, improve operational efficiency, and drive economic growth in Colombia’s textile sector.

Previous: Advanced Single Jersey Terry Circular Knitting Machine Gains Momentum in India

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.