Advanced Single Jersey Terry Circular Knitting Machine Gains Momentum in India

Jul 25, 2025

India’s textile and apparel sector is evolving rapidly, driven by increasing consumer demand for comfortable, stylish, and high-performance fabrics. Among the most transformative innovations contributing to this shift is the Single Jersey Terry Circular Knitting Machine, a versatile and high-efficiency solution tailored for today’s dynamic fashion and textile landscape.

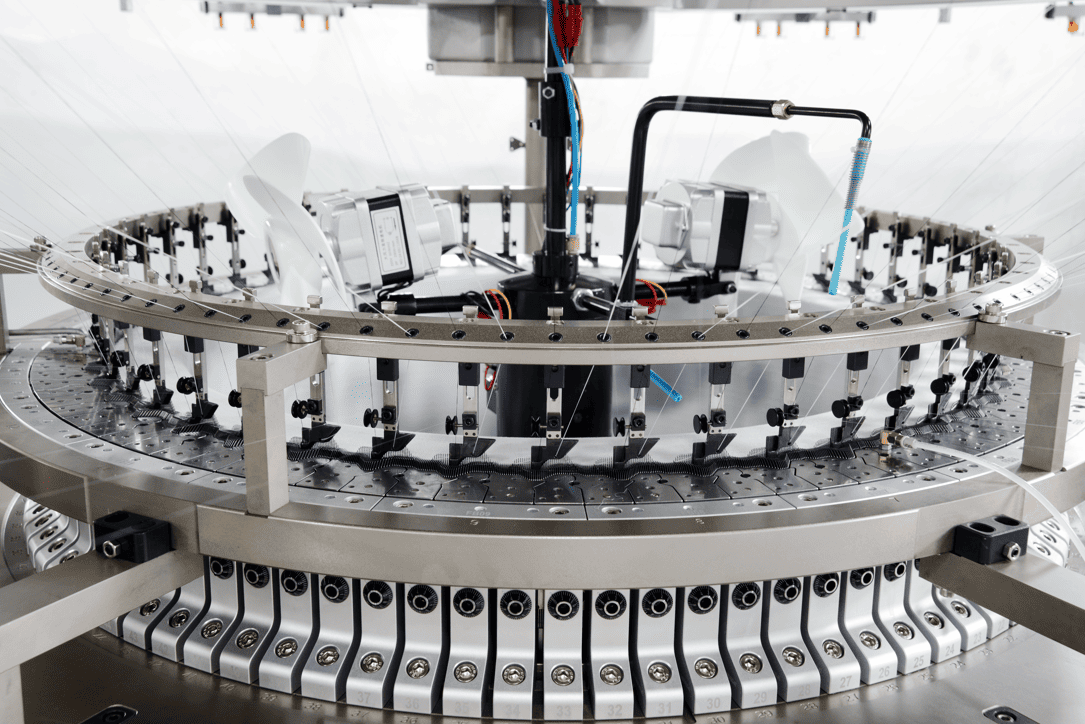

Designed with precision engineering and cutting-edge automation, the single jersey terry circular knitting machine combines high-speed production, superior fabric quality, and creative flexibility. It is quickly gaining popularity in the Indian market, where manufacturers are seeking advanced tools to remain competitive and meet rising demand across categories such as casual wear, sportswear, loungewear, and home textiles.

The single jersey terry circular knitting machine operates using a single-sided loop formation method. In simple terms, this means that during the knitting process, loops are formed only on one side of the fabric, while the reverse side remains smooth. This structure enhances both the aesthetic appeal and functional comfort of the material.

From soft cotton tees and lightweight sweaters to plush bathrobes, fashionable headwear, and breathable bedding, the texture-rich output of single-sided terry circular knitting machines enables a wide range of textile products to feature eye-catching designs and superior comfort. With just one machine, manufacturers can meet diverse design needs and maintain a strong presence in both domestic and export markets.

One of the standout features of the single jersey terry circular knitting machine is its highly customizable terry design capability. By adjusting the size, shape, and density of the loops (or "terry"), designers can create an expansive array of textures and finishes. This flexibility supports brands aiming to offer distinctive, fashion-forward products with enhanced consumer appeal.

Thanks to its intelligent control system, the machine allows for seamless transitions between different weaving effects. A single operator can switch between patterns, loop depths, and fabric thicknesses with minimal downtime, enabling greater experimentation and creative freedom. This level of automation and design control helps Indian textile manufacturers remain agile in responding to ever-changing fashion trends.

The single jersey terry circular knitting machine is engineered for maximum productivity without compromising quality. It incorporates high-speed rotating needle plates and sophisticated knitting technology that ensures fast yet precise operations. In high-volume production environments, such as those found in India’s textile hubs like Tiruppur, Ludhiana, and Surat, speed and reliability are non-negotiable — and this machine delivers on both fronts.

Moreover, the machine is equipped with a central raising and lowering system, allowing easy adjustment of fabric weight and tightness. This helps ensure consistent output quality across different fabric compositions and applications.

Additionally, its built-in intelligent monitoring system provides automatic alerts for mechanical issues or operational faults. This predictive functionality minimizes unplanned downtime and helps ensure the stability of production lines — a crucial advantage for manufacturers operating in time-sensitive supply chains.

Product Name: Single Jersey Terry Circular Knitting Machine

Diameter Range: 6 to 44 inches

Gauge Options: 14 to 44 gauge

Number of Feeders:

18F to 132F (3 feeders/inch)

24F to 176F (4 feeders/inch)

Compatible Materials:

Pure cotton, chemical fiber, blended yarns, silk, and artificial wool

This wide compatibility allows for smooth integration into existing production setups, enabling manufacturers to diversify their product offerings with ease. Whether working with natural or synthetic fibers, the machine adapts seamlessly to various yarns while maintaining stable operation.

The machine is equipped with a 4-track cam seal design, featuring knit cams, tuck cams, and miss cams. This combination enhances the intricacy and diversity of fabric patterns that can be produced, catering to both aesthetic and functional textile requirements.

The central raising/lowering system allows fine-tuned control over fabric weight and thickness, essential for creating garments with specific tactile properties or weight-based performance needs.

To meet the growing demand for stretch fabrics, the feeding yarn carrier has been specially designed to work efficiently with Lycra and spandex yarns. An added middle yarn transfer ring improves ergonomics and operational visibility, making it easier for technicians to handle yarns without coming into direct contact with moving parts.

The ergonomic design ensures that yarn handling is safe, comfortable, and efficient. The free-floating yarn system reduces mechanical interference while enhancing stability during high-speed operations.

By swapping specific components, the machine can be effortlessly converted into a 3-thread fleece machine, a terry machine, or other specialty variations. This multi-purpose adaptability makes it a cost-effective investment for manufacturers serving multiple product segments.

The addition of spandex yarn during the knitting process opens the door to a new class of high-performance fabrics. These materials offer greater elasticity, making them ideal for activewear, intimate apparel, and other garments where stretch and recovery are critical. With the growing popularity of fitness and wellness-oriented lifestyles across India, the demand for such fabrics is on the rise.

The Single Jersey Terry Spandex Fabric Circular Knitting Machine is specifically engineered to handle these requirements with precision, producing fabrics that are not only soft and breathable but also resilient and form-fitting.

India’s textile industry is the second-largest in the world and continues to be one of the country’s most significant economic contributors. With a strong foundation in cotton and blended yarn production, and a well-established ecosystem of spinning, weaving, and garment manufacturing, India is ideally positioned to adopt advanced circular knitting technologies.

The shift toward value-added, fashion-centric, and performance-based textiles is already underway. This trend, combined with government support through schemes like PLI (Production Linked Incentive) and Make in India, is creating an environment ripe for innovation and modernization.

Manufacturers seeking to reduce labor dependency while increasing output and design capabilities will find the single jersey terry circular knitting machine a compelling solution. Whether catering to domestic retailers or serving global fashion brands through export, this machine offers a significant competitive edge.

The Single Jersey Terry Circular Knitting Machine is more than just a piece of equipment — it is a catalyst for innovation, productivity, and growth. Its combination of speed, flexibility, and high-quality output makes it an essential investment for forward-thinking textile businesses in India.

As the industry continues to evolve and align with global standards, adopting such state-of-the-art machinery will be key to capturing new opportunities in fashion, performance wear, and technical textiles. Whether you're a medium-sized fabricator or a large-scale manufacturer, the path to higher efficiency, better fabric quality, and expanded market reach starts here.

Next: Single Jersey Open Width Knitting Machine to Transform Colombia’s Textile Industry

Previous: Difference Between Double and Single Jersey Circular Knitting Machines

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.