Open Width Single Jersey Circular Knitting Machine: Advancing Fabric Quality and Production Efficiency

Dec 05, 2025

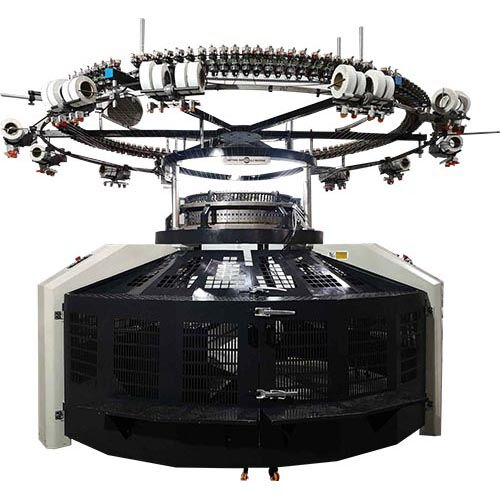

The textile industry continues to evolve rapidly, driven by rising demands for high-quality knitted fabrics, shorter production cycles, and improved operational efficiency. Among the technologies contributing to this transformation, the Open Width Single Jersey Circular Knitting Machine stands out for its ability to deliver crease-free, smooth, and uniform fabrics across a broad range of applications. Designed by building upon the foundation of traditional single-surface knitting machines, this advanced equipment eliminates drawbacks commonly seen in tubular knitting, particularly issues related to center creasing, fabric distortion, and post-processing waste.

Combining the strengths of both tubular and open-width knitting mechanisms, the machine provides an elevated production experience that enables textile mills to meet diverse market demands—from casual wear and activewear to high-performance technical textiles. This article explores in detail the features, advantages, operating principles, and application opportunities of the Open Width Single Jersey Circular Knitting Machine, showcasing why it has become a preferred choice for modern knitting factories.

The development of the Open Width Single Jersey Circular Knitting Machine originates from efforts to improve the output quality of traditional single jersey tubular machines. While tubular machines are efficient and widely used, they sometimes create creases or breaks at the center of the fabric, which become problematic during dyeing, finishing, or cutting. Manufacturers increasingly needed a machine that could retain the advantages of tubular knitting while delivering a seamless, crease-free fabric surface.

Building upon the architecture of the original single-surface machines, designers introduced new mechanisms that guide the fabric to be laid flat, eliminating the tubular form. This innovation allowed the production of open-width fabric directly on the machine, significantly reducing reliance on cutting, slitting, and post-processing adjustments. As a result, textile mills benefit from improved material utilization, higher efficiency, and reduced waste—making the machine an attractive investment for both small and large manufacturers.

One of the most defining advantages of the Open Width Single Jersey Circular Knitting Machine is its ability to produce high-quality fabric free from center breaks or creasing. This feature is particularly valuable for applications in which visual appearance and fabric hand feel are crucial, such as swimwear, T-shirts, tights, sportswear, and premium cotton textiles.

By guiding the fabric to exit the knitting zone in an open-width format rather than a tubular form, the machine prevents compression lines or fold marks from forming. This translates into a more visually appealing final product and reduces the need for corrective finishing processes, creating substantial long-term savings.

Traditional tubular fabrics often require slitting or reshaping during finishing, leading to unavoidable waste. With the open-width approach, the fabric is already delivered in the correct orientation, eliminating the loss associated with trimming or reshaping. This directly improves material utilization, making the machine particularly beneficial for large-scale production facilities where every percentage of saved fabric contributes to enhanced profitability.

For textile manufacturers, achieving maximum return on investment (ROI) is always a priority. The Open Width Single Jersey Circular Knitting Machine contributes significantly to improved efficiency through:

reduced downtime

minimized post-processing steps

longer needle lifespan

consistent fabric quality

Over time, these factors combine to deliver improved production output while lowering operating costs.

The machine successfully integrates the best attributes of simple jersey machines and telalibre systems, offering enhanced flexibility, improved stitch stability, and optimized fabric structure. This hybrid advantage gives textile engineers wider creative freedom in both design and material composition.

A standout feature of this machine is the Central Stitch Adjustment (CSA) mechanism. This design allows the operator to make precise, centralized adjustments to fabric density, ensuring uniform stitch formation across the entire fabric width. With easy access and simple controls, CSA:

enhances the consistency of fabric density

reduces production errors

simplifies switching between fabric types

This function is especially valuable when processing delicate or stretch-sensitive materials such as Lycra, spandex-blended yarns, synthetic fibers, or technical textiles.

With the open-width knitting process, materials such as Lycra are processed in a stable and controlled manner. This ensures:

uniform elasticity

consistent tension distribution

smooth fabric winding free of folds

For products such as sportswear, compression garments, and swimwear, uniform texture and reliable stretch properties are essential. The machine’s engineering ensures a high-quality finish that enhances wearability and visual appeal.

Operational smoothness is another core advantage of the Open Width Single Jersey Circular Knitting Machine. Equipped with an enhanced gearing system, the machine delivers:

smoother rotation

reduced mechanical friction

minimized vibration during high-speed knitting

longer life for key components

Machine operators benefit from easier adjustments and reduced strain during long production hours. For factory managers, this translates into stable operation across multiple shifts and reduced maintenance costs.

The machine is built using high-strength materials and precision-engineered needles designed to withstand demanding industrial environments. The adjustable fabric density and optimized yarn feeding system significantly reduce needle stress, leading to a longer operational lifespan and fewer interruptions from needle breakage or replacement.

Operators of all skill levels can easily adapt to the machine’s intuitive controls. The simple, ergonomic layout ensures:

quick learning curve

fast adjustment capability

user-friendly control panel

clear visibility of stitch settings

These features help factories reduce training time and improve production workflow, making the machine suitable for both large-scale industrial operations and smaller specialized knitting workshops.

Scale markings around the machine’s circumference help the operator maintain precise distance between the fabric ends. This contributes to:

accurate inch-by-inch operation

reliable reproduction of fabric specifications

consistent quality during long production runs

Such precision is essential for manufacturers working with high-end fashion textiles or technical fabrics requiring tight tolerances.

The versatility of the Open Width Single Jersey Circular Knitting Machine makes it ideal for a wide range of industries, including:

T-shirts

Polo shirts

Casual tops

Summer wear

The smooth, crease-free surface enhances comfort and aesthetic value.

Gym suits

Compression garments

Running apparel

Yoga wear

The machine effectively handles Lycra, spandex, elastic cotton, and blended functional fibers.

High elasticity and uniform density help produce:

seamless panties

undershirts

soft-touch loungewear

Its ability to process synthetic fibers such as nylon and elastane makes it perfect for stretch-intensive applications like:

swimwear

tights

leggings

performance suits

The machine can also handle specialized yarns used in:

mesh fabrics

breathable technical cloth

protective textiles

lightweight industrial fabrics

As technical textiles continue to grow in demand across industries such as medical, automotive, and outdoor products, the machine’s capability to process complex material blends gives manufacturers a competitive edge.

The Open Width Single Jersey Circular Knitting Machine is compatible with a wide variety of yarns, including:

cotton

synthetic fibers (polyester, nylon, spandex blends)

silk

artificial wool

mesh materials

elastic cloth

urethane elastic fibers

With a specialized yarn feeder, the machine can create diverse fabric structures such as:

plated fabrics

diamond pique

twill

cockled textures

double thread velvet

pique mesh

cotton-synthetic blends

This versatility enables textile mills to rapidly switch between production orders without major equipment modifications.

As global consumer expectations continue to rise, textile factories need machines that deliver consistent quality, operational stability, and flexible production capabilities. The Open Width Single Jersey Circular Knitting Machine meets these needs by providing:

reliable performance

reduced waste

enhanced operator experience

long-term durability

support for complex fabric structures

As manufacturers seek to differentiate themselves in a highly competitive market, machines with advanced features like CSA, precision scale markings, improved gearing systems, and multi-yarn compatibility will play an even more important role in shaping the future of knitted fabric production.

The Open Width Single Jersey Circular Knitting Machine represents a significant step forward in knitting technology. By combining the traditional advantages of single-surface machines with the added benefit of crease-free open-width output, it elevates fabric quality while improving production efficiency. Its human-oriented design, precise engineering, and ability to accommodate various yarn types make it an indispensable machine for modern textile factories.

With growing applications in fashion, sportswear, swimwear, underwear, and technical textiles, this machine continues to empower manufacturers with the tools needed to innovate and thrive in today’s fast-paced textile landscape.

Next: High Frame Circular Knitting Machines: Revolutionizing Modern Textile Manufacturing

Previous: Polyester Double Jersey Heath Cloth Circular Knitting Machine for Russia

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.