High-Efficiency Fleece Production: Exploring the Three Thread Circular Knitting Machine

Jan 14, 2026

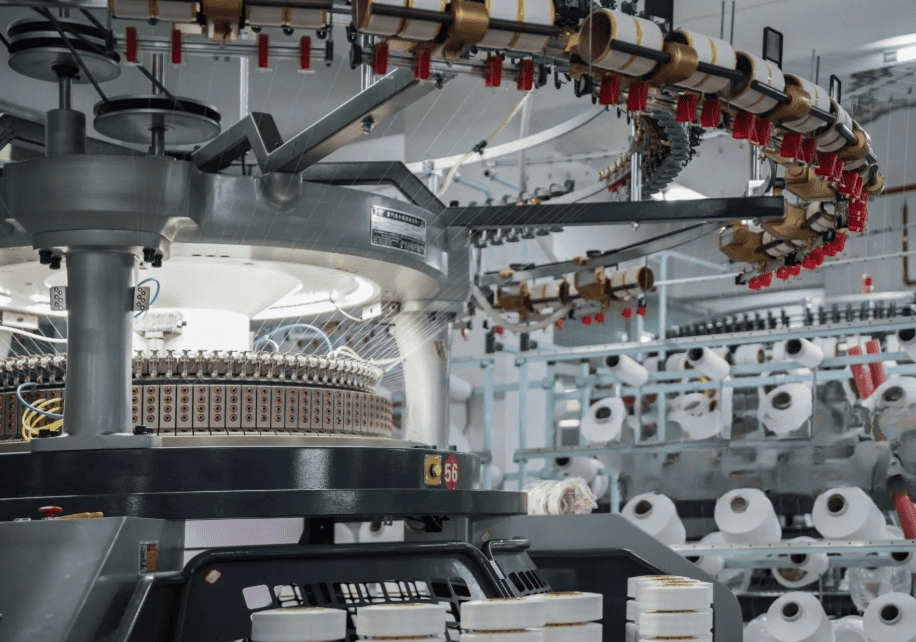

The global textile industry is undergoing a transformative phase, fueled by technological innovation, evolving consumer preferences, and the growing demand for sustainable, high-performance fabrics. Among the most significant breakthroughs in this field is the Three Thread Fleece Circular Knitting Machine — a state-of-the-art piece of industrial equipment that has rapidly become essential for manufacturers seeking to produce high-quality fleece fabrics efficiently and consistently. By combining advanced engineering, flexible operation, and robust design, this machine is redefining how textile producers meet market demands and maintain competitiveness on a global scale.

Fleece fabrics have emerged as a dominant force in contemporary textile markets due to their unique combination of softness, warmth, and versatility. From athleisure and sportswear to children's clothing and home textiles, fleece offers attributes that consumers increasingly value: comfort, thermal insulation, and aesthetic appeal. As demand for these fabrics grows, manufacturers require machinery capable of delivering not only high output but also precise control over fabric structure and texture. The Three Thread Fleece Circular Knitting Machine provides exactly that, bridging the gap between traditional textile methods and the needs of modern production lines.

The Three Thread Fleece Circular Knitting Machine is designed specifically for producing three-end fleece fabrics using a circular knitting process. Unlike conventional single-yarn circular machines, this machine uses three independent yarn feeds:

Ground yarn: Forms the primary fabric base.

Binder yarn: Interconnects loops, ensuring structural integrity.

Fleece yarn: Floats on the back loops to produce the soft, plush texture characteristic of fleece fabrics.

By simultaneously knitting these three yarns, the machine can create fabrics with superior softness, thermal properties, and durability — attributes critical for apparel, technical textiles, and home textiles. The circular design ensures continuous production of seamless tubular fabric, which enhances efficiency and reduces defects, making it ideal for high-volume manufacturing.

This advanced knitting technique enables manufacturers to engineer fabrics with varied loop structures, densities, and weights, allowing for products ranging from lightweight fleece for sportswear to dense, insulating fleece for winter apparel.

Fleece fabrics have become increasingly relevant in the modern textile market. Their popularity is largely driven by consumer lifestyle trends such as casual wear, athleisure, and functional outdoor apparel. Fleece offers warmth without excessive weight, excellent breathability, and a soft hand feel — making it versatile for a variety of applications.

Moreover, the market demand extends beyond fashion and sportswear. Fleece is widely used in children's apparel, blankets, throws, robes, and home furnishings, reflecting the growing consumer preference for comfort-oriented fabrics in everyday life. For manufacturers, this presents an opportunity to diversify product lines without significant additional investment in machinery, as a single Three Thread Fleece Circular Knitting Machine can produce a wide range of fabric types.

Additionally, the rise of sustainable textiles has boosted the appeal of fleece made from recycled fibers or eco-friendly blends. Manufacturers are now expected to deliver not only functional and aesthetically pleasing fabrics but also environmentally responsible products, further highlighting the importance of modern, adaptable knitting technologies.

The success of the Three Thread Fleece Circular Knitting Machine stems from several cutting-edge features:

The machine's three-yarn configuration allows precise control over each yarn's tension and placement, ensuring consistent loop formation and a uniform fabric texture. This flexibility enables manufacturers to customize fabric thickness, loop structure, and plushness, catering to specific product requirements. The multi-yarn system also reduces the risk of defects such as uneven pile height or loop misalignment, which can compromise fabric quality and appearance.

Modern machines feature centralized stitch control systems, allowing operators to adjust multiple stitch cams simultaneously. This innovation reduces downtime, simplifies machine setup, and improves consistency across production batches. By automating stitch adjustments, manufacturers can maintain precise loop formation while minimizing operator error, ensuring the finished fabric meets stringent quality standards.

Efficiency is a critical consideration in textile production. Three Thread Fleece Circular Knitting Machines are designed for high-speed knitting, enabling significant increases in output without compromising fabric quality. Additionally, energy-efficient drive systems and optimized power transmission mechanisms reduce operational costs while lowering environmental impact, aligning with global sustainability goals.

The machine's modular design allows conversion to single jersey or terry knitting with minimal adjustments. By replacing cylinders, cams, sinkers, and yarn guides, manufacturers can quickly adapt the machine to produce different fabric types. This adaptability ensures that factory investments remain future-proof, allowing businesses to respond to shifting market trends without purchasing additional equipment.

Many modern machines integrate digital monitoring systems, IoT connectivity, and automated yarn feeding. These technologies allow real-time performance tracking, predictive maintenance, and remote diagnostics, helping reduce downtime and optimize production efficiency. Manufacturers can track machine performance, detect anomalies, and adjust settings without stopping production, further enhancing operational efficiency.

The Three Thread Fleece Circular Knitting Machine provides unparalleled control over fabric properties, resulting in consistent high-quality fleece with the following advantages:

- Uniform texture and loop formation, reducing defects.

- Soft hand feel and thermal insulation, critical for apparel and home textiles.

- Dimensional stability, ensuring fabrics maintain shape during finishing and garment production.

- Reduced material waste, achieved through precise yarn feeding and tension control.

These benefits allow manufacturers to meet the demanding standards of premium brands while minimizing production costs and material losses.

The global fleece fabric market has seen steady growth over the past decade, driven by the increasing popularity of athleisure, casual wear, and functional outdoor clothing. Manufacturers in Asia, Africa, and Europe are adopting Three Thread Fleece Circular Knitting Machines to expand their production capabilities, enhance product quality, and compete in both domestic and export markets.

Developing textile hubs such as Bangladesh, Pakistan, Egypt, and Turkey have recognized the strategic value of investing in modern circular knitting technologies. The machine's flexibility allows manufacturers to work with a wide range of fibers, including cotton, synthetic blends, and recycled yarns. This versatility is particularly advantageous for meeting the requirements of diverse markets and consumer segments, from high-end fashion brands to mass-market sportswear producers.

Fleece fabrics are integral to contemporary wardrobes, including hoodies, sweatshirts, joggers, and casual outerwear. The machine's ability to produce soft, durable, and comfortable fabrics aligns perfectly with these applications.

Performance-oriented fleece fabrics provide both warmth and moisture management, making them ideal for outdoor sportswear, thermal mid-layers, and gym clothing.

Soft, lightweight, and warm fleece fabrics are perfect for children's wear, baby blankets, and sleepwear, where comfort and safety are paramount.

Heavyweight fleece produced on these machines is used in thermal underwear, insulated jackets, and protective cold-weather gear, offering superior heat retention and comfort.

Beyond clothing, fleece is widely used in blankets, throws, robes, and other lifestyle textiles, demonstrating the machine's versatility and broad market applicability.

Sustainability is a critical concern in modern textile manufacturing. The Three Thread Fleece Circular Knitting Machine supports eco-friendly production in several ways:

- Reduced energy consumption compared to older equipment, lowering operational carbon footprints.

- Minimized material waste through precise yarn handling and tension control.

- Compatibility with recycled and sustainable yarns, enabling manufacturers to produce eco-conscious fabrics.

These features align with the growing emphasis on green manufacturing practices and meet consumer demand for environmentally responsible products.

While the benefits are clear, adopting advanced knitting machinery requires careful planning. Challenges include:

- Workforce training: Skilled operators are required to manage and maintain complex machines.

- Maintenance: Precision components require regular inspection and lubrication to ensure consistent performance.

- Integration: Machines must be incorporated into existing production workflows without disrupting output.

Industry experts recommend that manufacturers combine machine adoption with digital monitoring systems, predictive maintenance, and operator training programs to maximize efficiency and ROI. Companies that invest in both technology and workforce development achieve the best outcomes in terms of production speed, fabric quality, and operational reliability.

Several textile manufacturers have reported tangible improvements after deploying Three Thread Fleece Circular Knitting Machines:

- Higher production capacity: Machines enable faster throughput and reduced cycle times.

- Enhanced customization: Manufacturers can produce fabrics with varying pile heights, textures, and weights, catering to diverse product lines.

- Reduced downtime: Centralized stitch control and automated monitoring reduce maintenance interruptions, increasing operational efficiency.

These real-world experiences highlight how strategic adoption of advanced circular knitting technologies can give manufacturers a competitive edge in both domestic and international markets.

The textile industry continues to evolve, and circular knitting technology is advancing alongside it. Emerging trends include:

- IoT-enabled smart machines: Offering remote monitoring, diagnostics, and performance optimization.

- AI-assisted process control: Enabling predictive adjustments to yarn tension, stitch patterns, and loop formation.

- Sustainable yarn integration: Machines capable of handling recycled fibers, eco-blends, and high-performance yarns.

- Increased automation: Reducing labor intensity and ensuring consistent production across multiple shifts.

The Three Thread Fleece Circular Knitting Machine is well-positioned to adapt to these developments, providing manufacturers with the tools needed to remain competitive, efficient, and responsive to consumer trends.

The Three Thread Fleece Circular Knitting Machine represents a paradigm shift in textile manufacturing. Its advanced multi-yarn knitting system, centralized control, energy efficiency, and modular design combine to deliver high-quality, versatile, and sustainable fleece fabrics. By enabling manufacturers to produce fabrics that meet the exacting standards of modern markets — from fashion apparel and sportswear to children's clothing and home textiles — this machine is not only a technical achievement but also a strategic business asset.

As consumer demand for comfort, performance, and sustainability continues to rise, manufacturers equipped with advanced circular knitting technologies are better positioned to deliver high-value products, optimize operational efficiency, and remain competitive in a rapidly changing global market. The Three Thread Fleece Circular Knitting Machine is more than just a tool; it is a gateway to innovation, growth, and long-term industry leadership.

Next: How High Speed Double Jersey Knitting Machines Increase Productivity and Quality

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.