Computerized Jacquard Knitting Machines: Boosting Efficiency and Design Flexibility for Manufacturers

Jan 10, 2026

The textile industry has undergone significant transformation over the past few decades, driven by advancements in technology, automation, and design innovation. Among the most impactful developments is the rise of computerized Jacquard knitting machines. These machines have revolutionized the way intricate patterns, designs, and textures are produced in knitwear, enabling manufacturers to achieve high levels of precision, efficiency, and customization that were once impossible with traditional manual or mechanical methods.

This article explores the technology, applications, benefits, and future prospects of computerized Jacquard knitting machines, highlighting why they have become indispensable for modern textile production.

The Jacquard principle dates back to the early 19th century, initially applied in weaving. Joseph Marie Jacquard, a French inventor, developed a system of punched cards that allowed looms to automatically produce complex woven patterns without manual intervention. This principle—automating pattern selection for intricate designs—laid the foundation for modern Jacquard machines, including knitting applications.

In knitting, Jacquard technology allows independent control of each needle, enabling the creation of highly detailed patterns, motifs, and textures. Traditional knitting machines were limited in design capabilities; they required manual manipulation for pattern changes and were restricted to simpler geometrical shapes. Jacquard knitting overcame these limitations, opening a new era for textile designers and manufacturers.

Computerized Jacquard knitting machines combine the Jacquard principle with modern computer control systems, allowing pattern data to be programmed digitally. This provides unprecedented accuracy, speed, and flexibility in fabric production.

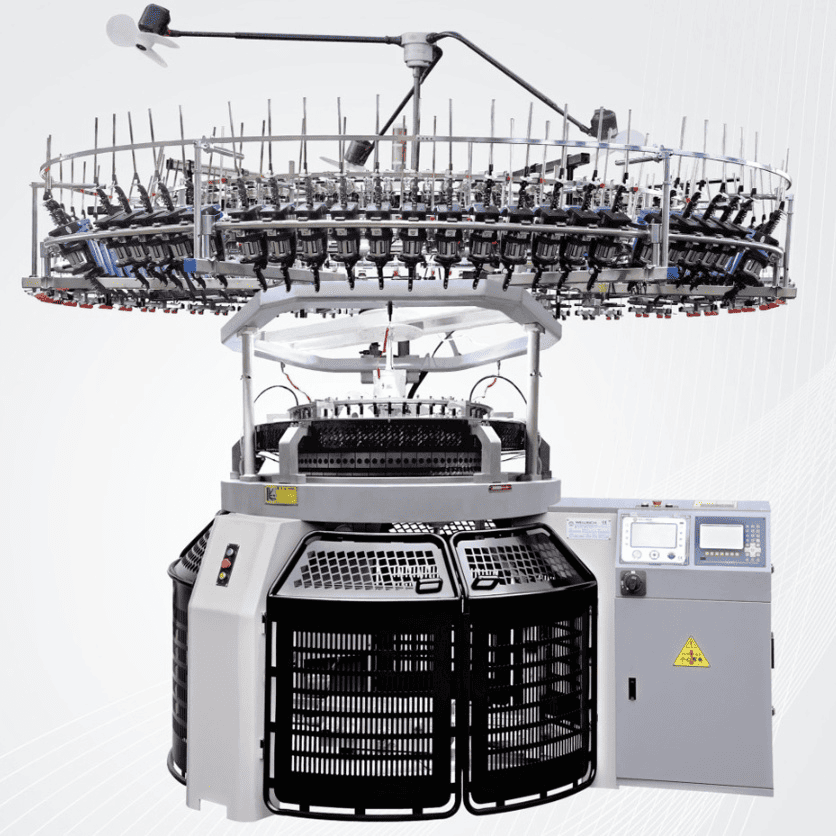

Computerized Jacquard knitting machines consist of several integrated components, each contributing to the machine's efficiency and functionality:

Needle Bed and Needles: The machine includes a full array of needles arranged in a bed, which can be operated independently to form complex patterns. The needles’ motion is electronically controlled based on the programmed design.

Jacquard Control System: The core of the system is the Jacquard controller, which interprets digital design data and activates the corresponding needles. Modern controllers can store thousands of patterns, allowing for easy retrieval and modification.

Computer Interface: Operators use dedicated software to create, import, or modify patterns. Designs can be uploaded from CAD or textile design software, ensuring smooth integration between creative teams and production lines.

Yarn Feeding System: Precision yarn feeders supply multiple yarns, including varied colors, textures, or fibers, enabling complex colorwork and multi-layered fabrics.

Tensioning and Take-Up Devices: These components maintain consistent yarn tension and fabric take-up, ensuring uniformity and high-quality fabric output.

Sensors and Automation: Advanced machines include sensors for detecting yarn breaks, needle malfunctions, and fabric defects, allowing real-time corrections and reducing waste.

The versatility of computerized Jacquard knitting machines makes them valuable across numerous textile applications:

The fashion industry is among the largest beneficiaries of computerized Jacquard knitting. Designers can create highly detailed sweaters, cardigans, and dresses with intricate motifs, including florals, geometrics, and branded patterns. Multi-color knitting, intarsia designs, and textured stitches are easily achievable, reducing the need for embroidery or printing while maintaining superior fabric integrity.

Computerized Jacquard knitting is increasingly used for technical and functional textiles, including automotive interiors, sportswear, medical textiles, and industrial fabrics. For example:

- Automotive seat covers with integrated patterns or mesh textures

- Compression garments with variable elasticity zones

- Protective textiles with layered or reinforced structures

The precision and flexibility of computerized Jacquard machines allow manufacturers to produce functional fabrics with performance-oriented features tailored to specific applications.

Home textiles, such as blankets, cushion covers, curtains, and upholstery fabrics, benefit from the high aesthetic value of Jacquard patterns. Computerized control enables large-scale production of detailed motifs with consistent quality and minimal defects.

In today’s market, personalization and on-demand production are increasingly important. Computerized Jacquard knitting machines can produce small batches of customized patterns without extensive setup or tooling changes, making them ideal for limited edition or bespoke products.

Adopting computerized Jacquard technology brings a wide range of benefits for manufacturers, designers, and end-users:

One of the primary advantages of computerized control is accuracy. Each needle is activated according to precise digital instructions, ensuring that every repeat of the pattern is identical. This eliminates human errors inherent in manual or mechanical Jacquard systems and produces high-quality, uniform fabrics.

Digital programming allows manufacturers to experiment with complex designs, multiple colors, and varying textures without physical modifications to the machine. Design iterations are faster, easier, and more cost-effective, giving brands a competitive advantage in rapidly changing markets.

Computerized Jacquard knitting machines automate processes that previously required manual intervention. This reduces labor costs, minimizes production time, and allows for higher output without compromising quality. The ability to detect yarn breaks, needle errors, or tension inconsistencies further improves efficiency by reducing waste and downtime.

These machines can handle multiple yarns simultaneously, enabling advanced techniques such as intarsia, tuck stitches, and multi-layer fabrics. Designers can create intricate textures, three-dimensional patterns, and jacquard effects in a single production run, reducing the need for secondary finishing processes.

Computerized Jacquard machines are fully compatible with CAD systems and other design software, enabling direct translation of digital artwork into textile patterns. This integration streamlines the workflow from design to production, fostering innovation and speeding up time-to-market.

The precision and automation inherent in computerized Jacquard knitting minimize yarn waste caused by errors, misalignment, or inconsistent tension. Efficient yarn management systems ensure optimal usage, contributing to cost savings and sustainability efforts.

The past decade has seen continuous advancements in computerized Jacquard knitting, driven by digitalization, smart manufacturing, and material science. Notable innovations include:

Modern machines operate at faster knitting speeds without compromising quality. High-speed needle selection enables rapid production of intricate patterns and reduces overall cycle time.

Yarn feeding technology now supports multiple fiber types and diameters, including cotton, wool, synthetic blends, and technical filaments. Multi-feed systems allow complex color patterns and varied textures within a single fabric.

Sensors and AI-powered monitoring systems detect potential machine issues, such as needle wear or yarn tension irregularities, before they cause production interruptions. Predictive maintenance ensures higher uptime and longer machine lifespan.

Energy-efficient motors, automated tension control, and optimized knitting algorithms reduce power consumption, aligning textile production with sustainable manufacturing initiatives.

The demand for computerized Jacquard knitting machines is growing worldwide, driven by several key factors:

Rise in Demand for Customized Textiles: Consumers increasingly seek personalized apparel and home textiles, making flexible, on-demand production essential.

Growth in Technical and Functional Textiles: Industries such as sports, healthcare, and automotive require fabrics with performance features, many of which can be achieved through computerized Jacquard knitting.

Advancements in Smart Textile Integration: Conductive yarns and wearable technology are being incorporated into fabrics, requiring precise needle control for functional integration.

Digital Transformation in Manufacturing: As factories adopt Industry 4.0 practices, computerized knitting machines provide data-driven insights, remote monitoring, and production optimization.

China: A leading manufacturer and exporter of computerized Jacquard knitting machines, with high production capacity and competitive pricing.

Europe: High adoption of premium machines for fashion and technical textiles, emphasizing quality and sustainability.

North America: Focused on innovation, integrating computerized Jacquard technology with smart textile and wearable solutions.

While the benefits are clear, manufacturers and textile businesses must consider several challenges when adopting computerized Jacquard knitting machines:

Advanced machines require significant capital expenditure. However, cost savings from automation, reduced labor, and improved efficiency often justify the investment over time.

Operators must have knowledge of digital design, machine programming, and textile properties. Training programs and skilled personnel are essential for maximizing machine potential.

High-tech components, including controllers, sensors, and needle systems, require regular maintenance. Reliable suppliers and technical support are critical to ensure minimal downtime.

Integrating computerized Jacquard machines into existing production lines may require adjustments to material handling, quality control, and design processes.

Several textile manufacturers worldwide have successfully implemented computerized Jacquard knitting machines to improve efficiency, expand design capabilities, and enter new markets:

Fashion Industry: Luxury brands in Europe use computerized Jacquard machines to produce high-end knitwear with complex motifs, reducing reliance on embroidery and hand-finishing.

Sportswear: Leading sports brands utilize multi-yarn Jacquard knitting to create seamless, breathable garments with performance-oriented zones for flexibility and support.

Home Textiles: Textile manufacturers produce patterned blankets, cushions, and upholstery fabrics with consistent quality and reduced production time.

Technical Applications: Automotive and medical textile producers leverage precise patterning and layered knitting for reinforced, functional fabrics.

The future of computerized Jacquard knitting is promising. Ongoing advancements in automation, AI integration, and smart textiles will further expand machine capabilities. Potential developments include:

- Integration with wearable technology, incorporating sensors and conductive threads directly into fabrics

- AI-assisted design optimization, predicting the best knitting patterns and yarn combinations for efficiency and aesthetics

- Eco-friendly production, using sustainable fibers and energy-efficient machinery to reduce the environmental footprint

- Fully connected factories, where machines communicate with supply chains and production management systems in real time

These innovations will further position computerized Jacquard knitting as a cornerstone of modern textile manufacturing, combining artistry, precision, and technological sophistication.

Computerized Jacquard knitting machines have transformed the textile industry, bridging the gap between traditional craftsmanship and digital manufacturing. By enabling precise, high-speed, and versatile knitting, these machines empower designers and manufacturers to create complex patterns, multi-layered fabrics, and functional textiles with unprecedented efficiency.

From fashion and home textiles to technical and industrial fabrics, the applications are vast. Coupled with smart software, AI monitoring, and sustainable practices, computerized Jacquard knitting machines are shaping the future of textile production.

For manufacturers seeking to innovate, increase efficiency, and expand design possibilities, investing in computerized Jacquard knitting technology is no longer optional—it is essential.

As the textile industry continues to evolve, these machines will remain at the forefront, driving innovation, productivity, and creativity in fabrics worldwide.

Next: High-Efficiency Fleece Production: Exploring the Three Thread Circular Knitting Machine

Previous: Rib and Interlock Knitting Machines: Core Technology for High-Quality Knitted Fabrics

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.