Binding Thread Lining Fleece Circular Round Knitting Machine: Revolutionizing Pakistan’s Textile Industry

Oct 20, 2025

The textile industry has been a cornerstone of Pakistan’s economy for decades, contributing significantly to national exports and providing employment for millions of workers. With the rise of global competition and rapidly evolving fashion trends, Pakistani textile manufacturers face constant pressure to innovate, improve efficiency, and maintain high product quality. In this context, the Binding Thread Lining Fleece Circular Round Knitting Machine emerges as a game-changing solution.

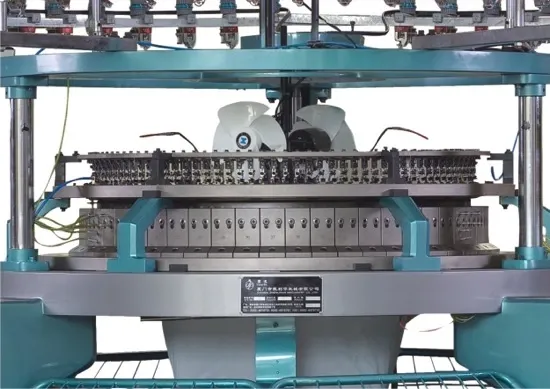

This advanced circular knitting machine is designed not only for producing high-quality fleece fabrics but also for handling a wide range of textile products with unmatched efficiency and precision. Its cutting-edge engineering and ergonomic design make it an ideal choice for textile factories seeking to expand their product portfolio while maintaining high standards in production.

From cozy fleece blankets to warm apparel and specialty fabrics, this machine empowers manufacturers to produce versatile, high-demand textile products efficiently and reliably. Its combination of technological innovation, operational flexibility, and operator-friendly design ensures that textile producers in Pakistan can meet domestic and international market demands effectively.

The Binding Thread Lining Fleece Circular Round Knitting Machine is engineered with specifications that make it suitable for both small-scale workshops and large industrial textile operations:

Diameter Range: 6–44 inches, allowing manufacturers to produce fabrics of varying widths suitable for apparel, home textiles, and industrial applications.

Gauge Options: 14–44 Gauge, providing flexibility in producing light, medium, and heavy-weight fabrics.

Feeder Quantity:

18F to 132F (3 feeders/inch)

24F to 176F (4 feeders/inch)

Supported Materials: Pure cotton, chemical fibers, mixed fibers, silk, artificial wool, and Lycra blends, enabling manufacturers to cater to diverse market demands.

The machine’s wide range of diameters, gauges, and feeders allows textile producers to create fabrics ranging from delicate, fine-knit garments to heavy fleece blankets, meeting a variety of consumer needs with a single, multipurpose machine.

The Binding Thread Lining Fleece Circular Round Knitting Machine incorporates several innovative features that distinguish it from conventional knitting machines:

The machine features a 4-track cam seal design that integrates knit cams, tuck cams, and miss cams. This advanced configuration allows precise stitch formation, uniform fabric texture, and seamless patterning. The cam system is designed to minimize stitch errors, reduce yarn breakage, and ensure high-quality output at high speeds.

This system allows operators to adjust fabric weight conveniently and quickly, enabling uniform fabric density across production batches. The central lifting and lowering mechanism significantly reduces setup time between different fabric types and ensures consistent fabric quality.

A unique feature of this machine is its ergonomic feeding yarn carrier, optimized for Lycra and other specialty yarns. The carrier ensures smooth yarn movement, prevents tangling, and maintains yarn tension even during high-speed operations. Its design keeps the yarn system at a safe distance from the operator’s body, improving workplace safety and operator comfort.

The middle yarn transfer ring facilitates efficient yarn monitoring and handling, ensuring stability during high-speed knitting. This feature allows operators to oversee production effortlessly while maintaining consistent yarn feeding, reducing waste, and enhancing overall efficiency.

The machine is highly versatile. By replacing core components, it can be converted into:

3-thread fleece machines

Terry cloth machines

Specialized knitting machines for unique fabric applications

This flexibility makes the machine a valuable asset for factories seeking to diversify production without investing in multiple dedicated machines.

The Binding Thread Lining Fleece Circular Round Knitting Machine caters to a wide range of fabric applications:

Textile manufacturers can produce soft, warm, and durable garments, including hoodies, jackets, sweatshirts, and winter wear. The machine’s precise control over stitch patterns ensures high-quality fabric texture suitable for both casual and premium apparel.

The machine is ideal for creating blankets, throws, bed linens, and other home textile products. Its ability to knit thick and cozy fleece fabrics ensures comfort, warmth, and longevity, enhancing the value of end products.

The machine’s compatibility with Lycra, silk, mixed fibers, and artificial wool makes it suitable for technical fabrics used in sportswear, medical textiles, and industrial applications. Manufacturers can create fabrics with enhanced elasticity, durability, and texture to meet specific functional requirements.

The machine’s advanced cam system and optimized yarn feeding mechanism enable high-speed operation without compromising quality. This allows factories to increase production capacity while maintaining uniform fabric quality.

The central lifting and lowering system, combined with ergonomic yarn handling, allows operators to adjust settings quickly, reducing machine downtime and increasing overall productivity.

Precision-engineered components ensure uniform stitch formation, resulting in consistent fabric density, texture, and appearance. This minimizes defects, reduces waste, and improves profitability.

By maintaining distance between yarn carriers and operators, the machine enhances workplace safety. Its ergonomic design also reduces operator fatigue, supporting longer, more efficient working shifts.

The machine’s multipurpose functionality allows a single unit to serve multiple knitting applications, eliminating the need for separate machines for fleece, terry, and other fabric types. This reduces capital investment while maximizing production flexibility.

The Pakistani textile industry is one of the largest in Asia, producing millions of tons of fabrics annually. With growing domestic demand for winter clothing and home textiles, along with a strong export market, there is an increasing need for versatile and efficient knitting machinery.

Investing in the Binding Thread Lining Fleece Circular Round Knitting Machine offers several advantages:

Enhanced competitiveness: Manufacturers can produce a wider range of products efficiently, meeting both local and international standards.

Cost-effectiveness: Reduced downtime, energy efficiency, and multipurpose functionality lower operational costs.

Innovation opportunities: Ability to handle specialty yarns, Lycra blends, and mixed fibers enables producers to create high-value fabrics with unique properties.

By adopting advanced knitting technology, Pakistani textile producers can improve their market position, increase export potential, and enhance profitability in an increasingly competitive industry.

Consider a textile factory in Punjab aiming to expand its winter clothing line. Using the Binding Thread Lining Fleece Circular Round Knitting Machine, the factory can:

Produce high-quality fleece fabric with uniform thickness and smooth texture

Handle cotton, wool, and Lycra blends to create premium winter wear

Convert the machine into a 3-thread fleece setup to experiment with layered fabric designs

Achieve higher production speed without compromising fabric quality

The results: faster production, reduced labor costs, and diversified product offerings, giving the factory a competitive edge in both domestic and export markets.

Modern textile production requires eco-friendly and energy-efficient solutions. This circular knitting machine is designed to consume less energy per unit of fabric, reducing electricity costs and environmental impact. Its precise yarn handling reduces material waste, promoting sustainable textile manufacturing practices.

The Binding Thread Lining Fleece Circular Round Knitting Machine represents a new era in Pakistan’s textile industry. With its advanced technology, multipurpose functionality, and operator-friendly design, it empowers manufacturers to produce high-quality fleece fabrics efficiently, diversify their product range, and stay competitive in the global market.

By integrating precision cam systems, ergonomic yarn carriers, and flexible conversion options, this machine meets the evolving needs of textile manufacturers in Pakistan. It is ideal for producing soft apparel, cozy home textiles, and specialty fabrics with minimal downtime, consistent quality, and operational safety.

Investing in this advanced circular knitting machine is not just a purchase—it is a strategic step towards enhanced productivity, market competitiveness, and long-term growth. For textile producers seeking to meet growing domestic demand, compete internationally, and innovate continuously, the Binding Thread Lining Fleece Circular Round Knitting Machine is the ultimate solution.

Next: Double Knit Fabrics: Manufacturing with Circular Round Knitting Machines

Previous: How Circular Knitting Machines Are Revolutionizing Sportswear and Yoga Wear Production

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.