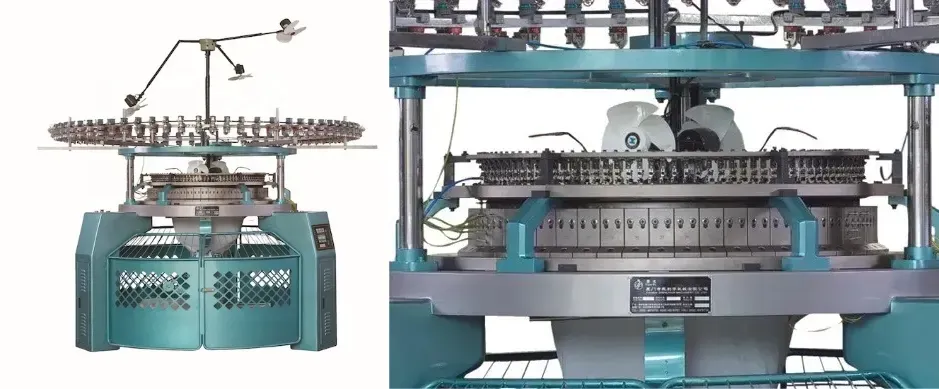

Single Jersey Pattern Wheel Circular Knitting Machine for Algeria

Sep 08, 2025

The textile and garment industry in Algeria is rapidly expanding, fueled by growing domestic demand, rising exports, and technological investments from international machinery suppliers. Among the most important innovations driving efficiency and quality in this sector is the single jersey pattern wheel circular knitting machine, a versatile and high-precision system designed to meet the diverse production requirements of modern fabric manufacturers.

Known for producing high-quality single jersey fabrics in a wide range of designs, thicknesses, and colors, this machine represents the perfect balance of engineering precision and practical usability. With the addition of advanced cam technology and a multi-stage pattern wheel, Algerian manufacturers now have the opportunity to significantly enhance production speed, fabric consistency, and design variety while maintaining operational efficiency.

This article explores the technical details, market impact, and practical advantages of adopting the single jersey pattern wheel circular knitting machine in Algeria.

Algeria’s textile industry is currently undergoing modernization as the country looks to reduce its reliance on imports and boost its role as a competitive fabric and garment exporter. A machine capable of delivering consistent, high-volume output while adapting to diverse fabric requirements is essential for this vision.

The single jersey pattern wheel circular knitting machine fits this need by producing:

Mesh fabrics

Ponte-de-Roma fabrics

High elastic Lycra fabrics

Swimwear fabrics

Other single jersey varieties

With versatility as its hallmark, the machine enables Algerian producers to cater to both domestic markets — where casual wear and activewear are on the rise — and international buyers who demand stringent quality standards.

The machine comes with a variety of customizable features, enabling Algerian textile manufacturers to select configurations that match their exact production goals.

Product Type: Single Jersey Pattern Wheel Circular Knitting Machine

Diameter Range: 6 – 44 inches

Gauge Options: 14 – 44 gauge

Number of Feeders:

18F to 132F (3 feeders per inch)

24F to 176F (4 feeders per inch)

Material Compatibility: Pure cotton, chemical fibers, mixed fibers, silk, and artificial wool

This broad specification range highlights the adaptability of the machine to a variety of yarn types, enabling local factories to switch easily between natural fibers, synthetics, and blends.

At the heart of the machine’s performance is the four-track cam seal design. Equipped with knit cams, tuck cams, and miss cams, the design allows operators to create intricate and varied fabric structures with high precision.

Knit cams ensure uniform looping.

Tuck cams add texture and design depth.

Miss cams provide opportunities for complex patterns and lightweight fabric options.

Together, these cams expand the creative potential of fabric producers while ensuring machine stability at high speeds.

The fabric weight adjustment system is designed for quick and convenient control. Operators can fine-tune fabric density and thickness without halting production, ensuring smooth transitions between orders and maximizing output efficiency.

Lycra and other elastic fibers are notoriously challenging to handle due to their stretch and delicacy. The machine’s special yarn feeding carrier makes Lycra integration seamless, ensuring high-quality stretch fabrics suitable for activewear, sportswear, and swimwear.

With its middle transfer ring design, operators can easily monitor yarn handling without compromising comfort or safety. The machine ensures smooth operation without interference to the worker’s body, which reduces fatigue during long production cycles.

One of the standout qualities of the machine is its ability to transform into different types of knitting machines. By replacing key components, it can function as:

A 3-thread fleece machine

A terry fabric machine

Other fabric variants

This adaptability minimizes capital investment for Algerian textile manufacturers while maximizing production diversity.

The streamlined cam-wheel system and ergonomic design allow the machine to run at high speeds without compromising quality. This enables local factories to boost their production volumes to meet growing market demand.

Consistency in stitch formation, precision in yarn feeding, and advanced fabric weight adjustment result in uniform and superior fabric quality. This is essential for international buyers and for positioning Algerian textiles competitively in export markets.

Instead of investing in multiple machines for different fabric types, Algerian producers can rely on one system with modular adaptability. This lowers upfront investment and ongoing maintenance costs.

The user-friendly design reduces the physical strain of long operating hours. Improved ergonomics translate to higher efficiency and fewer errors during operation.

The single jersey pattern wheel circular knitting machine is designed to meet the demands of multiple textile applications:

Cotton-based single jerseys form the backbone of T-shirts, casual tops, and undergarments.

Lycra-enhanced fabrics ensure elasticity, comfort, and durability, perfectly suiting athletic clothing.

Specialized high-elastic fabrics ensure resistance to wear and tear from water and chlorine exposure.

With tuck and miss cam designs, manufacturers can produce stylish and unique textiles for designers and brands.

Mixed fibers and artificial wools can be knitted into durable fabrics for industrial or specialty use.

The integration of advanced knitting technologies such as the single jersey pattern wheel circular knitting machine is expected to significantly strengthen Algeria’s textile competitiveness. With the government promoting industrial diversification and private companies seeking to modernize their operations, this machine can serve as a catalyst for growth.

Industry experts forecast that demand for sportswear and fashion apparel in North Africa will increase steadily over the next decade. By leveraging versatile machines like this, Algerian factories can secure a greater share of both regional and global textile markets.

Consider a medium-sized Algerian textile factory focusing on cotton casual wear. By adopting this machine, the factory can:

Increase production capacity by 30–40%

Diversify product offerings to include Lycra-based sportswear

Reduce operational costs by eliminating the need for multiple machine types

Improve worker safety and comfort with ergonomically designed features

Such benefits demonstrate why the machine is considered a strategic investment for textile producers across Algeria.

As circular knitting technology continues to evolve, features like digital monitoring, automated pattern adjustment, and real-time performance data may become standard. Integration with Industry 4.0 platforms will allow Algerian manufacturers to remotely monitor production, optimize efficiency, and reduce downtime.

The single jersey pattern wheel circular knitting machine is already built with modularity in mind, which positions Algerian manufacturers to adopt future upgrades without requiring full system replacements.

The single jersey pattern wheel circular knitting machine represents more than just an advanced piece of textile machinery — it is a solution designed for versatility, efficiency, and growth. With features such as the four-track cams design, high-precision adjustment systems, and ergonomic operator-friendly structure, this machine enables Algerian textile manufacturers to produce a wide range of fabrics that meet both domestic needs and international standards.

As Algeria’s textile industry continues to grow and modernize, embracing cutting-edge knitting technology will be essential. By investing in machines that deliver flexibility, reliability, and high-quality output, Algerian producers can secure their role in the global textile supply chain while reducing reliance on imports.

The future of Algeria’s textile manufacturing sector lies in innovation and adaptability — and the single jersey pattern wheel circular knitting machine is an ideal step toward that future.

Next: Double Jersey Electronic Jacquard Knitting Machine: Advanced Technology for Modern Fabrics

Previous: Key Parts and Functions of a Circular Knitting Machine

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.