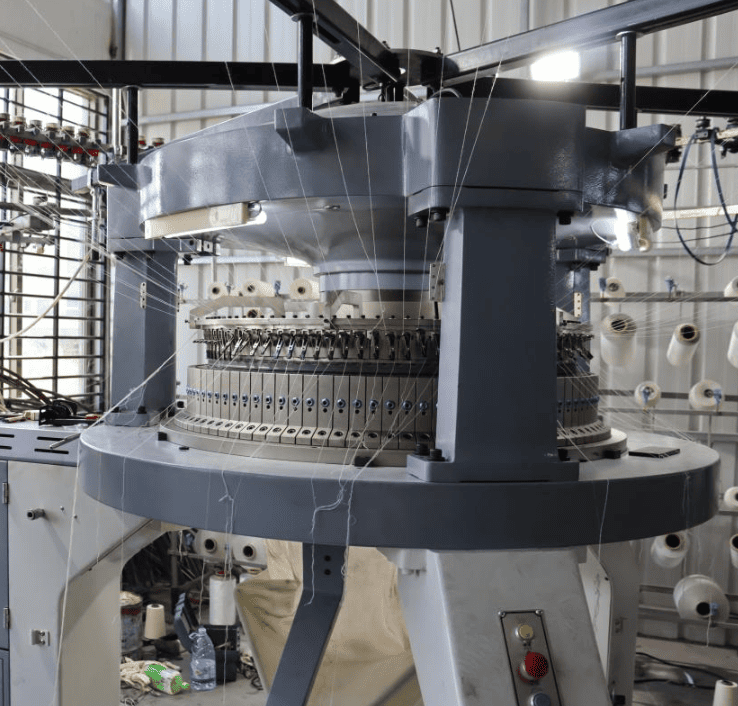

Single Jersey Circular Knitting Machine for Myanmar: Enhancing Textile Production with Precision and Efficiency

Aug 15, 2025

Myanmar’s textile industry is witnessing a significant transformation with the introduction of advanced knitting technology. Among the most notable innovations is the Electronic Single Terry Fabric Circular Knitting Machine. Designed to meet the growing demands for high-quality fabric production, this machine combines versatility, precision, and efficiency, making it an ideal choice for textile manufacturers in Myanmar looking to enhance their competitiveness in both domestic and international markets.

The Electronic Single Terry Fabric Circular Knitting Machine is designed for single jersey and terry fabric production. Its specifications cater to a wide range of knitting requirements:

Diameter: 6 to 44 inches, accommodating small to large-scale production.

Gauge: 14 to 44 gauge, offering flexibility in fabric density.

Number of Feeders: 18F to 132F (3 feeders/inch) and 24F to 176F (4 feeders/inch), supporting high-speed operation.

Available Materials: Pure cotton, chemical fibers, blended fibers, silk, and artificial wool, enabling production of diverse fabric types.

This versatility ensures that manufacturers can meet varying customer requirements, from lightweight cotton garments to heavier terry fabrics.

The Single Jersey Circular Knitting Machine is built with features that enhance both the quality and efficiency of production:

The machine incorporates a 4-track cams seal system, including knit cams, tuck cams, and miss cams. This design ensures precise fabric formation and consistent loop structure, minimizing defects and improving fabric uniformity.

One of the standout features of this machine is its central raising and falling system, which allows for rapid and accurate adjustment of fabric weight. Manufacturers can easily modify fabric density to meet design specifications without interrupting production.

The machine is equipped with a specially designed feeding yarn carrier. This system improves the proficiency of Lycra and other specialty fibers, ensuring even tension and smooth feeding. Additionally, the ergonomic middle feeding yarn transfer ring allows operators to monitor and manage yarn efficiently, without the risk of physical contact with the machine, enhancing safety and comfort.

The machine is highly adaptable, capable of converting into 3-thread fleece, terry, and other types of knitting machines by replacing core components. This multipurpose functionality makes it a cost-effective solution for manufacturers who require flexibility in fabric production.

The integration of an advanced electronic control system optimizes machine performance, ensuring consistent stitch quality and high production efficiency. This system allows for precise adjustments, automated monitoring, and easy troubleshooting, reducing downtime and operational costs.

The introduction of the Electronic Single Terry Fabric Circular Knitting Machine in Myanmar offers several key advantages for textile manufacturers:

With high-speed operation and multiple feeders, the machine can produce larger volumes of fabric in shorter timeframes, meeting growing market demands.

The precise cam system and electronic control ensure consistent stitch formation, even fabric tension, and smooth surfaces, resulting in high-quality textiles suitable for premium garments.

The ability to work with cotton, chemical fibers, silk, and blends allows manufacturers to diversify their product offerings, catering to different market segments and trends.

Ergonomic designs and automated features reduce the physical strain on operators, improve workflow efficiency, and lower the risk of operational errors.

Multipurpose functionality allows manufacturers to switch between fabric types without investing in multiple machines, reducing capital expenditure while maximizing production capacity.

The Single Jersey Circular Knitting Machine is particularly suited for the production of:

Widely used for towels, bathrobes, and home textiles, terry fabrics require precise loop formation and consistent weight, both of which are easily achieved with this machine.

Commonly used in t-shirts, underwear, and lightweight garments, single jersey fabrics benefit from the machine’s uniform stitch quality and high-speed knitting capability.

By converting the machine into a 3-thread fleece or other specialty knitting setups, manufacturers can cater to niche markets that demand high-performance textiles.

For Myanmar’s textile industry, which is expanding its export capacity and domestic garment production, the machine offers an opportunity to increase competitiveness by producing higher-quality fabrics with greater efficiency.

Recognizing the importance of smooth machine operation, suppliers often provide comprehensive technical support and training for operators. Training includes:

Understanding machine components and their functions

Proper yarn feeding and tension adjustment

Maintenance procedures to minimize downtime

Conversion techniques for different fabric types

This support ensures that Myanmar’s textile workforce can operate the machines effectively, maximizing production output while maintaining fabric quality.

Modern textile machinery also addresses the growing need for sustainability. The Electronic Single Terry Fabric Circular Knitting Machine is designed to optimize energy consumption, reduce material waste, and enable efficient use of yarns. By ensuring precise fabric formation and reducing defects, the machine contributes to a more sustainable manufacturing process, aligning with global environmental standards and improving the brand image of textile manufacturers.

The introduction of the Electronic Single Terry Fabric Circular Knitting Machine in Myanmar represents a significant step forward in the country’s textile industry. By combining advanced technology, ergonomic design, multipurpose functionality, and electronic control systems, this machine allows manufacturers to produce high-quality fabrics efficiently and cost-effectively.

Its versatility in handling a wide range of materials, ease of operation, and adaptability to different fabric types makes it a valuable investment for textile factories aiming to expand their production capabilities. As Myanmar continues to grow as a textile manufacturing hub, machines like the Electronic Single Terry Fabric Circular Knitting Machine will play a pivotal role in enhancing productivity, fabric quality, and overall competitiveness in both domestic and international markets.

For manufacturers seeking to upgrade their production lines, embracing this technology offers a clear pathway to improved efficiency, better fabric quality, and greater market opportunities. With comprehensive technical support, ergonomic features, and sustainable operation, this machine exemplifies the future of textile manufacturing in Myanmar, helping the industry meet the evolving demands of modern fashion and home textile markets.

Next: How Double Jersey Circular Knitting Machines Are Transforming Fabric Production

Previous: Open Width Circular Knitting Machines: Transforming the Future of Textile Manufacturing

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.