Open Width Circular Knitting Machines: Transforming the Future of Textile Manufacturing

Aug 11, 2025

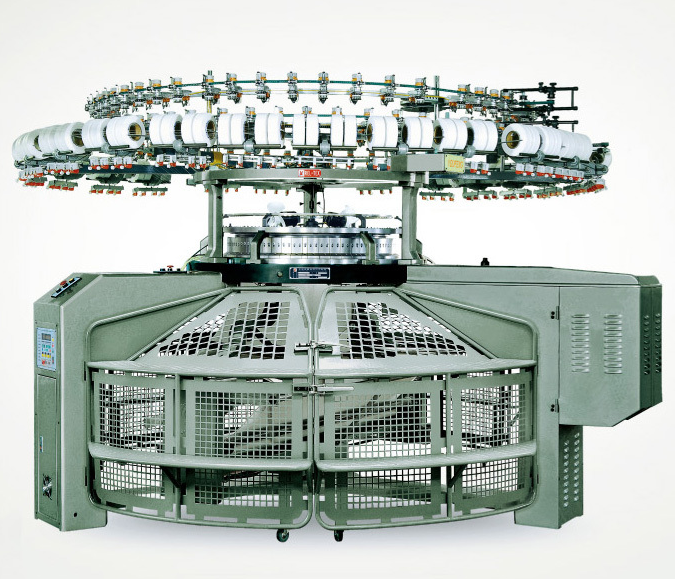

The textile industry is undergoing a transformative era driven by technological innovation, efficiency, and the increasing demand for sustainable manufacturing. Among the key innovations shaping this evolution is the Open Width Circular Knitting Machine. These machines have emerged as a cornerstone in modern textile production, particularly for creating seamless tubular fabrics and wide-width materials with exceptional speed, precision, and versatility.

Unlike conventional flat knitting systems that often require multiple seams and post-processing steps to achieve desired widths, Open Width Circular Knitting Machines can produce wide fabrics in a single pass, dramatically reducing labor costs and production time. This capability has not only boosted efficiency for manufacturers but also expanded creative possibilities for designers and product developers.

At the heart of this innovation is the principle of circular knitting — a process where yarn is continuously fed into the machine in a circular motion, interlooping to create fabric without the need for traditional seams. The “open width” capability means the knitted tube is automatically cut open during production, resulting in a flat fabric roll instead of a continuous tube.

This process brings together the best of both worlds: the high-speed productivity of circular knitting and the convenience of flat, seam-free fabrics that are ready for finishing and garment manufacturing.

One of the most compelling reasons manufacturers are shifting toward Open Width Circular Knitting Machines is production efficiency. Traditional flat knitting requires multiple panels to be joined together through labor-intensive sewing processes. Not only does this consume additional time and manpower, but it also introduces visible seams that can affect the appearance, comfort, and performance of the final product.

By contrast, open width circular knitting delivers:

Single-Pass Wide Fabric Production – Eliminating the need for sewing multiple panels together.

Reduced Labor Costs – Automation and minimal post-processing significantly cut manpower requirements.

Shorter Lead Times – Faster production cycles enable quicker delivery to market.

Enhanced Consistency – Automated tension control and precision knitting ensure uniform quality.

For manufacturers handling large-volume orders — such as those in sportswear, casualwear, upholstery, and industrial fabrics — these advantages translate directly into cost savings and higher profit margins.

Modern Open Width Circular Knitting Machines are far from simple mechanical devices. They are sophisticated, digitally controlled systems that integrate electronics, automation, and software to deliver maximum efficiency and versatility.

Some of the most notable features include:

Programmable Control Panels – Operators can set, adjust, and store knitting patterns digitally, allowing quick changeovers for different products.

Automatic Tension Adjustment – Maintaining consistent yarn tension is crucial for fabric quality, and these machines can automatically adapt to different yarn types and weights.

Variable Speed Settings – Precision speed control enables optimized knitting for both delicate and heavy fabrics.

Pattern Versatility – Machines can produce jacquard, rib, interlock, and other complex structures without extensive manual setup.

Integrated Cutting Systems – The knitted tube is slit into open width fabric as part of the same continuous process.

This level of automation not only improves efficiency but also reduces the dependency on highly skilled labor, which is a growing challenge in many manufacturing regions.

Versatility in yarn usage is one of the defining strengths of Open Width Circular Knitting Machines. They can handle:

Natural fibers – Cotton, wool, silk.

Synthetic fibers – Polyester, nylon, acrylic.

Blends – Combining natural and synthetic fibers for specific performance attributes.

This broad compatibility allows manufacturers to produce a wide range of products, from lightweight summer garments to heavy-duty technical textiles. For example:

Fashion Apparel – Seamless, smooth fabrics ideal for dresses, T-shirts, and activewear.

Home Textiles – Bed linens, blankets, and upholstery materials.

Industrial Applications – Protective clothing, filtration fabrics, and automotive textiles.

The flexibility to experiment with fiber blends also enables innovation in fabric performance — such as moisture management, antimicrobial properties, stretch recovery, and UV protection — without compromising production speed.

In recent years, sustainability has moved from being a marketing buzzword to a critical operational goal in the textile sector. Open Width Circular Knitting Machines contribute significantly to this objective in several ways:

Less Fabric Waste – The seamless knitting process and reduced cutting requirements minimize offcuts.

Energy Efficiency – Modern machines are designed to optimize motor usage and reduce idle energy consumption.

Extended Product Lifespan – Uniform knitting and reduced seam stress can improve garment durability.

Some manufacturers are even combining these machines with recycled yarns, further reducing environmental impact while maintaining high-quality production.

As global demand for textiles continues to rise — driven by fast fashion, sportswear trends, and industrial growth — manufacturers face the challenge of increasing output without sacrificing quality.

Open Width Circular Knitting Machines address this challenge through:

High-Speed Operation – Capable of producing hundreds of meters of fabric per shift.

Consistent Output – Automation ensures every meter of fabric meets strict quality parameters.

Scalable Production – Multiple machines can run simultaneously with minimal additional staffing.

This makes them ideal for both large-scale textile factories and medium-sized production facilities looking to scale up without excessive infrastructure investment.

While fashion remains one of the primary beneficiaries of this technology, the scope of applications is far broader:

Sportswear & Athleisure – Stretchable, breathable fabrics that move with the wearer.

Medical Textiles – Seamless compression garments, bandages, and patient apparel.

Automotive Textiles – Durable seat covers and interior fabrics.

Outdoor & Performance Gear – Weather-resistant and quick-drying materials for active lifestyles.

The adaptability of the machines makes them a valuable asset in markets where fabric performance is as important as appearance.

Beyond technical performance, Open Width Circular Knitting Machines offer strong economic advantages:

Lower Per-Unit Costs – Reduced labor, shorter production cycles, and minimal waste.

Faster ROI – High productivity and market adaptability accelerate investment payback.

Market Diversification – Ability to serve multiple industries with one machine type.

These benefits make them especially appealing for manufacturers in competitive markets where cost efficiency can make or break profitability.

The future of Open Width Circular Knitting Machines is closely tied to broader trends in textile manufacturing, including automation, digitalization, and sustainability. We can expect:

Smarter Machines – Integration with AI and IoT for predictive maintenance and real-time performance monitoring.

Greater Customization – Advanced patterning capabilities for on-demand fashion and short production runs.

Eco-Innovation – More energy-efficient motors, waterless dyeing compatibility, and integration with closed-loop recycling systems.

As global textile supply chains become increasingly complex, the ability to adapt quickly to changing demands will be a decisive advantage — and Open Width Circular Knitting Machines are positioned perfectly to meet this challenge.

Open Width Circular Knitting Machines are more than just a piece of equipment — they represent a shift toward faster, smarter, and more sustainable textile production. Their ability to produce wide-width fabrics seamlessly, accommodate diverse yarns, and integrate advanced automation makes them indispensable in the modern manufacturing landscape.

From reducing waste to expanding creative possibilities, these machines are helping manufacturers stay competitive in a market that demands both speed and quality. As technology continues to evolve, their role in shaping the textiles of tomorrow will only grow stronger.

In an industry where innovation and efficiency often decide success, Open Width Circular Knitting Machines stand as a clear example of how engineering excellence can transform not just production lines, but entire markets.

Previous: Single Jersey Auto-Striper Knitting Machine Launches in Indonesia

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.