How Circular Knitting Machines Are Revolutionizing Technical Textile Production

Nov 11, 2025

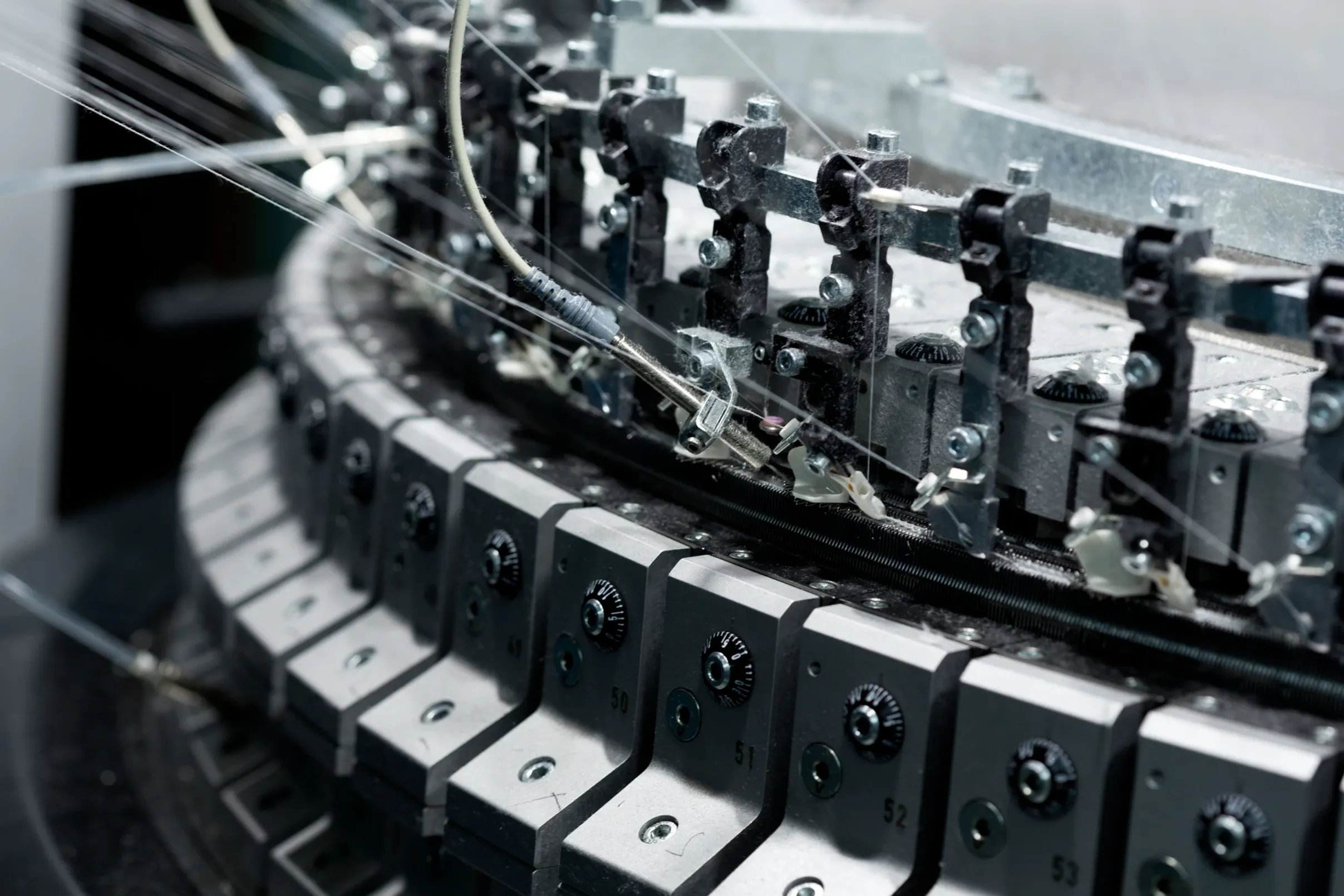

Circular knitted technical textiles represent a revolution in fabric manufacturing. Produced using circular knitting machines, these fabrics are designed for functional performance, combining characteristics such as durability, elasticity, and adaptability. Unlike woven textiles, circular knitting creates fabrics in a continuous tubular form without seams, which allows for superior flexibility and comfort. This seamless structure makes circular knitted fabrics especially valuable in applications that demand stretch, resilience, and form-fitting properties—from athletic wear and underwear to medical textiles and industrial applications.

In recent years, advancements in knitting technology have transformed circular knitting from a process used mainly for basic apparel into a sophisticated platform for producing high-performance technical textiles. Today’s machines can handle a wide range of yarns, including natural fibers like cotton and bamboo, as well as synthetic fibers such as polyester, nylon, and spandex. The resulting fabrics can be lightweight, breathable, water-resistant, antimicrobial, or thermoregulatory, depending on their intended use.

Circular knitted fabrics are now found everywhere—from everyday T-shirts to high-tech compression garments, sportswear, and even medical braces. This article explores the major categories of products made from circular knitted textiles and how modern knitting technology continues to shape the future of the textile industry.

Among the many applications of circular knitted textiles, T-shirt fabrics remain the most recognizable. These fabrics are typically produced using single-jersey or interlock knitting structures, each offering unique properties suited to different purposes.

Single-jersey fabric is lightweight, smooth, and has a natural stretch, making it the preferred choice for casual T-shirts. It is usually crafted from cotton, polyester, or a blend of both. On the other hand, interlock fabric features a double-knit construction that provides more stability, thickness, and opacity, making it suitable for premium T-shirts or polo shirts.

The ability to integrate stretch fibers such as spandex (elastane) into these knits enhances elasticity and comfort, ensuring the garments maintain their shape even after repeated washing. Furthermore, advanced dyeing and finishing techniques allow manufacturers to produce fabrics with superior colorfastness, moisture management, and softness.

Modern circular knitting machines can produce T-shirt fabrics at high speeds with precision in stitch density and texture, allowing textile manufacturers to customize fabrics according to brand requirements. From breathable summer wear to heavier-weight winter tops, circular knitted T-shirt fabrics combine comfort, performance, and aesthetic appeal, serving as the foundation of modern casual fashion.

The athleisure and sportswear segment has been one of the fastest-growing areas for circular knitted technical textiles. As consumers increasingly prioritize health, fitness, and comfort, the demand for fabrics that combine functionality, aesthetics, and performance continues to rise.

Circular knitting machines are essential in creating fabrics that meet the complex requirements of activewear. For example, polyester microfibers blended with spandex are commonly used to make leggings, sports bras, and compression tops. These fabrics are engineered for moisture-wicking, quick-drying, and four-way stretch capabilities.

The result is a garment that moves effortlessly with the body, provides consistent support, and enhances athletic performance. Circular knitted fabrics also offer excellent breathability and thermal regulation, making them suitable for both high-intensity workouts and casual wear.

One of the key advantages of circular knitted fabrics in this category is the ability to seamlessly integrate multiple functions into a single fabric layer. For example, a circular knitted sports shirt can feature zones of increased ventilation, compression, or reinforcement, all knitted directly into the material. This not only improves comfort but also eliminates the need for additional sewing, reducing friction and weight.

Furthermore, with the growing focus on sustainability, many manufacturers now produce eco-friendly athleisure fabrics using recycled polyester or bio-based fibers such as Tencel™ and bamboo. These materials retain high performance while minimizing environmental impact.

From yoga pants and training tops to outdoor jackets, circular knitted textiles continue to push the boundaries of innovation in activewear, meeting the evolving needs of performance-driven consumers.

Another area where circular knitting has made a transformative impact is intimate apparel and underwear. Consumers today demand more than just visual appeal—they want comfort, breathability, and functionality. Circular knitting, especially seamless knitting technology, has made it possible to achieve all of these goals simultaneously.

Seamless knitting allows for the creation of tubular garments that fit the natural curves of the body without seams, which eliminates chafing and improves comfort. These garments are often produced using fine-gauge circular knitting machines capable of intricate stitch patterns and variable fabric thickness within the same piece.

Common materials used in underwear and lingerie include cotton, bamboo, modal, and microfiber blends. Each material offers unique benefits:

Cotton provides natural softness and breathability.

Bamboo offers antibacterial properties and moisture control.

Modal is known for its silky touch and resistance to shrinkage.

Microfiber blends deliver a smooth, lightweight finish ideal for form-fitting garments.

The use of elastane fibers ensures that these fabrics offer a comfortable stretch while maintaining shape retention. Moreover, seamless knitting technology allows designers to incorporate ventilation zones or support panels directly into the fabric structure, enhancing both function and aesthetics.

Today, brands use circular knitting to create underwear that is not only practical but also stylish and sustainable. By minimizing fabric waste and reducing sewing operations, circular knitting has become an environmentally friendly approach to producing intimate apparel that feels like a “second skin.”

Circular knitted fabrics also play a key role in nightwear and loungewear, where comfort and softness are the top priorities. These garments are meant to provide relaxation, so the fabric must be gentle on the skin, lightweight, and breathable.

Popular materials include cotton, viscose, and bamboo blends, which are ideal for pajamas, robes, and lounge sets. The interlock and rib-knit constructions often used in nightwear ensure elasticity and durability while maintaining a cozy texture. Ribbed knits, in particular, add subtle stretch and structure, helping garments retain their shape after repeated use.

The modern loungewear trend has blurred the boundaries between homewear and streetwear. As a result, manufacturers now design circular knitted fabrics that not only provide comfort but also enhanced aesthetic appeal. Luxurious finishes, heathered textures, and gentle drapes have made these fabrics suitable for stylish casual outfits, combining relaxation with sophistication.

Circular knitting machines can also incorporate functional finishes such as anti-pilling, anti-odor, or temperature control, making loungewear ideal for both warm and cool climates. With the growing demand for sustainable comfort wear, circular knitted fabrics made from organic cotton, recycled fibers, and biodegradable yarns are gaining popularity in the global market.

Beyond everyday wear, circular knitted technical textiles are increasingly used in medical and protective applications, where performance and safety are critical. These fabrics are engineered to offer specific functionalities such as compression, elastic recovery, and moisture control.

In the medical field, circular knitted fabrics are used in compression garments, bandages, and orthopedic supports. Their seamless and elastic structure provides consistent pressure distribution, promoting blood circulation and aiding recovery. Knitted with specialized yarns, these textiles can also incorporate antimicrobial, hypoallergenic, or breathable properties, ensuring both hygiene and comfort.

Protective textiles, on the other hand, often require high strength and resilience. Circular knitting machines can produce fabrics with reinforced fibers such as aramid (Kevlar) or ultra-high-molecular-weight polyethylene (UHMWPE), offering resistance against cuts, abrasion, and heat. These fabrics are used in gloves, sleeves, and protective clothing for industrial workers, firefighters, and law enforcement.

The ability of circular knitting machines to blend performance yarns with comfort fibers makes them invaluable for technical and protective fabric manufacturing. As industries increasingly demand lightweight, breathable, and flexible protection, circular knitted textiles are becoming the preferred choice over traditional woven alternatives.

The future of circular knitted technical textiles is being shaped by rapid innovation in machine technology, smart yarns, and sustainability. Today’s advanced circular knitting machines are equipped with computerized controls, multi-feed systems, and automated tension adjustments, allowing for precise customization and higher productivity.

Circular knitting now enables the integration of electronic fibers and conductive yarns to produce smart textiles. These fabrics can monitor body temperature, heart rate, and muscle activity—paving the way for wearable health-monitoring garments. Smart knitted fabrics are already being used in sports performance tracking, rehabilitation, and patient care.

Sustainability has become a defining trend across the textile industry. Circular knitting naturally supports eco-friendly production, as it reduces fabric waste and energy consumption. Manufacturers are adopting recycled polyester, organic cotton, and bio-based fibers to minimize environmental impact. Furthermore, innovations such as waterless dyeing and closed-loop recycling are helping create more responsible production processes.

With the rise of digital knitting technologies, manufacturers can now produce customized fabrics on-demand with variable patterns, densities, and textures. This flexibility aligns with consumer demand for personalized fashion and reduced inventory waste. The ability to design and produce in small batches is especially advantageous for emerging brands and sustainable fashion initiatives.

Circular knitted technical textiles have evolved far beyond their traditional role in basic apparel. With their seamless construction, stretchability, and versatility, they have become the backbone of modern fabric innovation—supporting industries from fashion and fitness to healthcare and protective wear.

As technology, sustainability, and consumer expectations continue to advance, circular knitting will remain at the forefront of textile manufacturing. Its combination of efficiency, comfort, and adaptability ensures that the next generation of fabrics will not only look and feel better but also perform to meet the challenges of modern life.

Next: How Modern Circular Knitting Machines Transform Polar Fleece Manufacturing

Previous: Maintenance Tips for Rib Circular Knitting Machines

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.