Double Jersey Circular Knitting Machine for Angola

Apr 11, 2025

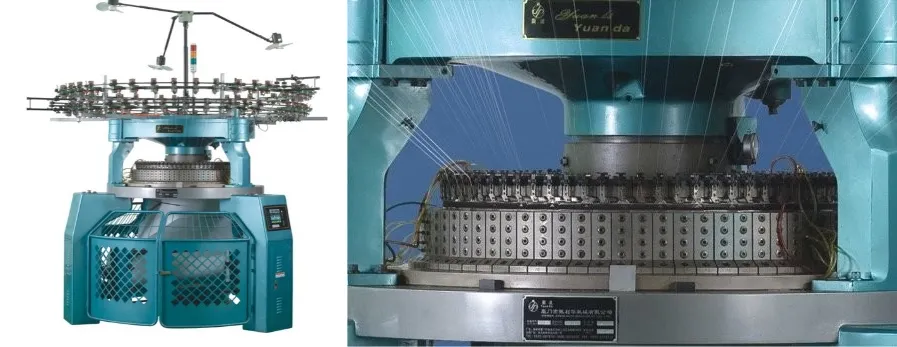

In an exciting development for the textile sector in Africa, a cutting-edge Double Jersey Body Size Interlock Circular Knitting Machine has been successfully delivered to a prominent knitwear production facility in Angola. This delivery marks a significant milestone in supporting the country’s growing garment and apparel manufacturing industry, reflecting both increased demand for high-performance knitwear machinery and the expansion of localized textile production across the African continent.

Angola’s garment industry is undergoing a rapid transformation. With government initiatives supporting industrial diversification and job creation, the demand for modern textile manufacturing equipment has surged. In response, this latest shipment of a Double Jersey Interlock Circular Knitting Machine aims to meet the rising local demand for high-quality interlock fabrics and value-added knitwear products.

The machine, renowned for its versatility, efficiency, and precise engineering, is designed to enhance productivity while delivering impeccable fabric quality. With the ability to produce a wide variety of double jersey fabrics, including high-grade apparel for both men and women, health-oriented textiles, and fashion-forward styles, it is perfectly aligned with the current market trends in Angola and beyond.

Product: Double Jersey Body Size Interlock Circular Knitting Machine

Diameter Range: 8 to 44 inches

Gauge Options: From 6 to 40 gauge

Feeder Quantity: 16 to 88/106 feeders (configurable based on production needs)

Fabric Types: Interlock fabrics, elastic health cloth, twill, air layer, double mesh, and various premium apparel textiles.

This wide range of options ensures that the machine can be tailored for different fabric weights, structures, and finishing characteristics—crucial for garment manufacturers aiming to diversify their product offerings.

One of the standout elements of this circular knitting machine is its sophisticated dial design. Both the lower and upper dials feature closed-track cams that support a range of knitting techniques—knit, tuck, and miss. This configuration provides unmatched flexibility in fabric design and pattern creation, a major advantage for manufacturers seeking to stay competitive in today’s fast-evolving textile markets.

Additionally, the machine includes an independently adjustable yarn feeder system, allowing for highly customized yarn delivery and tension control. When paired with the optional Lycra attachment, the machine seamlessly produces elastic double jersey fabrics, ideal for healthwear, sportswear, and fashion items requiring stretch and durability.

A notable advantage of this model is its modular construction, which offers long-term flexibility. The machine can be easily converted into a rib knitting machine, providing manufacturers with the ability to adapt quickly to shifting market needs without needing to invest in an entirely new setup.

This modularity reduces downtime, lowers costs, and increases production agility—particularly valuable for factories in developing markets like Angola where capital efficiency and machine longevity are critical factors in decision-making.

The decision to ship this high-performance knitting machine to Angola is a testament to the region’s growing prominence in global textile and apparel supply chains. With a renewed focus on “Made in Africa” manufacturing, countries like Angola are investing in modernizing their textile infrastructure. By adopting industry-leading technology such as this circular knitting machine, local manufacturers can produce fabrics previously imported from overseas, strengthening the local economy and creating new job opportunities.

Moreover, the introduction of this machinery is expected to raise the bar in terms of product quality, customization capability, and turnaround times, empowering Angolan manufacturers to meet both domestic demand and explore new export opportunities.

This model is not just a standard production machine—it is a powerful tool for textile innovation. With the ability to knit complex structures such as double mesh, air layer fabrics, and twill variations, the machine is ideal for manufacturers who want to push the boundaries of conventional knitwear.

Apparel brands, especially those targeting the premium menswear and womenswear segments, will find the output of this machine particularly appealing. The consistent loop formation, minimal fabric distortion, and superior elasticity control all contribute to final garments that are comfortable, stylish, and built to last.

In addition to its technical prowess, the machine emphasizes ease of use and operator efficiency. With ergonomic features, intuitive control panels, and streamlined maintenance access, it ensures that even first-time operators in developing manufacturing environments can quickly become proficient. This lowers the learning curve and accelerates the production ramp-up time for new factory setups.

The machine’s robust frame and reliable performance further make it ideal for environments with less predictable infrastructure, such as intermittent power supply or limited access to spare parts. The durable construction and simple maintenance protocols allow for continuous operation with minimal downtime.

The export of this Double Jersey Circular Knitting Machine to Angola also reflects the growing ties between machinery manufacturers in Asia and emerging industrial players in Africa. As African nations seek to reduce dependency on imports and boost domestic production, they are increasingly turning to trusted international partners who can provide the machinery, technical support, and training needed to build a modern industrial base.

In this instance, after-sales support has been arranged through a local technical service partner in Luanda, ensuring that the factory staff receives on-site guidance during installation, operator training, and regular machine servicing.

This development could signal the beginning of a new chapter for Angola’s—and Africa’s—textile industry. As the local manufacturing base matures, the need for advanced yet accessible machinery will only continue to grow. Equipment like the Double Jersey Body Size Interlock Circular Knitting Machine will play a central role in unlocking production potential and fostering innovation in garment manufacturing.

More than just a machine, this investment represents a commitment to quality, technology, and sustainable industrial growth. With the right blend of infrastructure, talent, and machinery, Angola is well-positioned to become a significant player in the African textile landscape.

With the successful delivery and commissioning of this high-tech Double Jersey Interlock Circular Knitting Machine, Angola’s textile sector takes a firm step toward modern manufacturing standards. This machine is poised to contribute significantly to the country's ambitions of becoming a self-sufficient, export-capable producer of knitted fabrics and garments.

As more countries across Africa invest in local manufacturing capabilities, innovations like these will serve as the backbone for a more diversified and resilient global textile industry.

Next: Double-Sided Interlock Knitting Machine Enters Peru's Textile Market

Previous: The Rib Circular Knitting Machine: A Technological Marvel in Modern Textile Production

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.