Complete Guide to Interlock Open Width Knitting Machines for Modern Textile Production

Feb 17, 2026

As global textile production continues to evolve toward higher efficiency, better fabric quality, and reduced material waste, advanced knitting technologies are becoming essential for manufacturers seeking competitive advantages. Among these innovations, the Interlock Open Width Circular Knitting Machine stands out as a highly specialized solution designed to combine superior fabric quality with streamlined production efficiency. By integrating interlock knitting technology with an open-width fabric output system, this machine addresses many of the challenges traditionally associated with circular knitting, including fabric creasing, uneven tension, and post-processing waste.

Unlike conventional circular knitting machines that produce tubular fabric requiring later cutting and unfolding, open-width designs deliver fabric in a flat, ready-to-process format. When paired with interlock knitting capability—which produces strong, smooth, and elastic double-knit fabrics—the result is a versatile production system capable of meeting the demands of modern apparel, sportswear, technical textiles, and specialty fabric markets.

With diameters ranging from 26 to 44 inches, gauges between 16 and 32, and feeder configurations from 52F to 83F per inch, interlock open width circular knitting machines offer manufacturers flexibility in production scale, fabric density, and end-use applications. This article explores their structure, working principles, technical specifications, performance advantages, and role in shaping the future of textile manufacturing.

An interlock open width circular knitting machine is an advanced textile production system designed to knit double-knit interlock fabrics while delivering the finished textile in an open-width format rather than as a tube. It merges two essential technologies:

- Interlock knitting mechanism: Produces dense, smooth, double-layered fabric with excellent stretch, durability, and dimensional stability.

- Open-width take-down system: Outputs flat fabric directly from the machine, eliminating the need for cutting tubular material.

This combination allows manufacturers to produce high-quality fabrics that require minimal finishing while improving workflow efficiency and reducing raw material waste.

Modern interlock open width machines are engineered with adjustable parameters to accommodate diverse textile requirements:

- Cylinder Diameter: 26–44 inches

- Gauge Range: 16–32 gauge

- Feeder Quantity: 52F–83F per inch

- Fabric Types: Swimwear, underwear, tights, T-shirts, polo shirts, sportswear, gym apparel, technical textiles, and more

These adjustable specifications allow textile producers to fine-tune machine performance based on yarn type, fabric structure, and production goals.

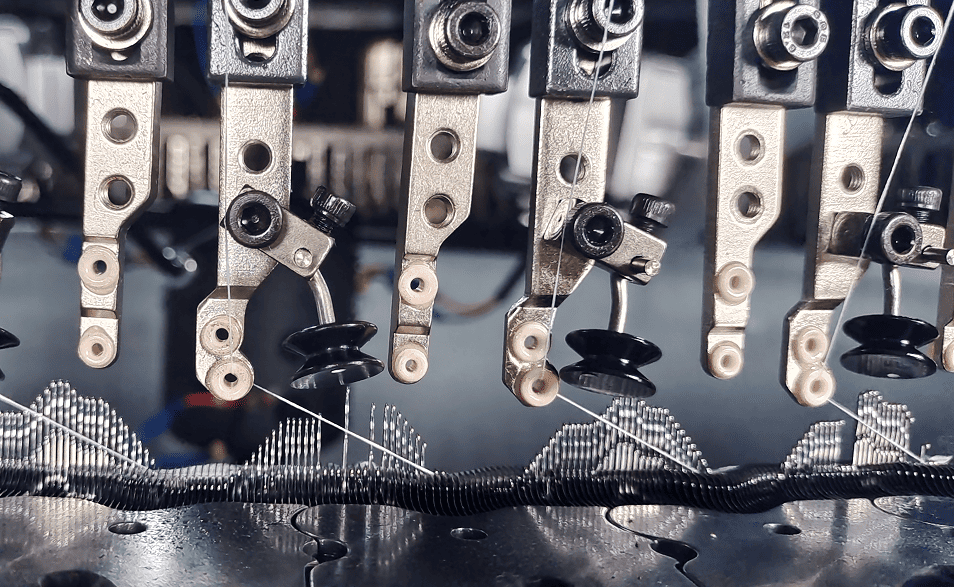

At the heart of the machine lies a precision-engineered circular knitting system consisting of a rotating cylinder and dial arrangement that works in synchronization to create interlock stitches. Yarn feeders supply threads evenly, while needles intermesh loops from both needle beds to form the double-knit structure.

Unlike standard circular machines that form tubular fabric, this system integrates a gear-driven open-width mechanism. Instead of allowing the fabric to remain in a continuous tube, the machine automatically opens and spreads it during production. This ensures the material exits in a flat sheet, ready for finishing or direct cutting.

A roller-controlled take-down unit maintains consistent tension throughout knitting, ensuring uniform stitch density and preventing distortion. The synchronized mechanical system balances yarn feed, needle movement, and take-down speed to achieve optimal fabric consistency.

One of the most valuable features of this machine is its ability to produce fabric without a central crease. Traditional tubular knitting often leaves fold marks that must be removed through additional finishing processes. By delivering fabric in open width, the machine eliminates this issue entirely, producing smooth, crease-free material across the entire surface.

This not only improves visual quality but also reduces downstream processing costs, since fewer finishing treatments are required.

The cloth collecting system is designed to roll fabric automatically as it is produced. This automated take-up function ensures:

- Smooth fabric handling

- Reduced operator intervention

- Stable tension control

- Adaptability to various fabric widths

Even smaller fabric pieces that might otherwise be difficult to process can be handled efficiently. The automated rolling mechanism enhances productivity and reduces labor requirements, allowing operators to supervise multiple machines simultaneously.

Modern textile machinery must prioritize operational safety and production reliability. Interlock open width circular knitting machines are equipped with automatic shutdown systems that activate if the fabric is not completely cut or if irregularities occur during operation.

This protective feature prevents:

- Fabric damage

- Yarn breakage

- Machine component stress

- Production waste

By stopping operation immediately when anomalies are detected, the system protects both the machine and the material, ensuring consistent production quality.

Uniform knitting tightness is critical for fabric quality, especially in high-performance textiles. The integrated roller speed adjustment device allows operators to fine-tune the take-down rate, ensuring consistent tension throughout the knitting process.

This capability enables manufacturers to:

- Adjust fabric density

- Maintain uniform stitch formation

- Optimize performance for different yarn types

- Improve final fabric appearance

Such precision control is essential for producing premium-grade textiles used in demanding applications like sportswear or technical garments.

These machines are engineered for high-speed operation without sacrificing quality. Thanks to optimized feeder configurations and efficient mechanical design, they can produce large volumes of fabric in relatively short time frames.

High productivity makes them ideal for large-scale manufacturing facilities supplying global apparel brands or textile distributors. At the same time, their precision ensures consistent results suitable for premium product lines.

Traditional double jersey knitting machines produce high-quality fabrics but typically output tubular material. Open-width machines eliminate folding marks but may lack certain structural capabilities. The interlock open width circular knitting machine merges both advantages into a single system.

This hybrid functionality provides:

- Strong, elastic fabric structure

- Smooth surface texture

- Flat output format

- Reduced finishing requirements

The result is a versatile production platform capable of meeting diverse textile demands.

Fabric quality is a decisive factor in textile competitiveness. Interlock open width machines are designed to produce premium fabrics characterized by:

- Smooth surface texture

- Excellent elasticity

- High dimensional stability

- Uniform stitch density

- Minimal distortion

Because the fabric is produced without central folds, manufacturers can reduce cutting waste during garment production. This directly improves material utilization rates and lowers production costs.

Thanks to their versatility, these machines support a wide variety of textile applications across multiple industries.

They are widely used for producing fabrics for:

- T-shirts

- Polo shirts

- Underwear

- Tights

- Sportswear

- Gym clothing

The interlock structure provides softness, stretch, and durability, making it especially suitable for garments worn close to the skin.

Modern athletic wear requires fabrics that combine comfort, flexibility, and durability. Interlock fabrics meet these requirements by offering:

- Breathability

- Moisture management compatibility

- Stretch recovery

- Resistance to deformation

This makes the machines ideal for manufacturing textiles used in fitness apparel, training gear, and performance uniforms.

Beyond fashion and apparel, interlock open width circular knitting machines are increasingly used for technical textiles. These materials may serve industrial, medical, or functional applications where consistency and structural integrity are essential.

Examples include:

- Compression fabrics

- Protective textiles

- Functional layered materials

- Specialized industrial fabrics

Efficiency is one of the main drivers behind adopting advanced knitting technology. These machines help manufacturers reduce costs in several ways:

- Lower labor requirements through automation

- Reduced fabric waste thanks to crease-free output

- Shorter production cycles due to high-speed operation

- Minimal post-processing requirements

Over time, these benefits translate into significant operational savings and improved profit margins.

Despite their advanced capabilities, interlock open width circular knitting machines are designed for user-friendly operation. Many models feature intuitive control panels, digital monitoring systems, and automated diagnostics.

Operators can quickly adjust settings such as:

- Stitch density

- Fabric tension

- Machine speed

- Yarn feed rate

Maintenance is simplified through modular component design, allowing technicians to replace or service parts efficiently. This reduces downtime and ensures consistent production schedules.

Sustainability is becoming a critical priority in textile manufacturing. These machines contribute to environmentally responsible production by:

- Minimizing fabric waste

- Reducing energy consumption through efficient operation

- Lowering chemical usage in finishing processes

- Supporting recyclable or eco-friendly yarn materials

The open-width design alone can significantly reduce scrap generated during garment cutting, helping manufacturers meet sustainability goals and regulatory standards.

|

Feature |

Conventional Circular Machine |

Interlock Open Width Machine |

|

Fabric Output |

Tubular |

Open width |

|

Crease Marks |

Possible |

Eliminated |

|

Fabric Strength |

Moderate |

High |

|

Waste Level |

Higher |

Lower |

|

Production Efficiency |

Standard |

High |

|

Application Range |

Limited |

Broad |

This comparison demonstrates how open-width interlock machines outperform traditional designs in both productivity and fabric quality.

Several global trends are accelerating demand for advanced knitting equipment:

- Rising demand for high-quality apparel

- Growth of athleisure and performance wear markets

- Increased focus on sustainable manufacturing

- Automation in textile production

- Expansion of technical textile sectors

Manufacturers investing in advanced machinery are better positioned to meet these market shifts while maintaining competitive pricing and product quality.

As textile technology continues to advance, future interlock open width machines are expected to incorporate even more intelligent features, such as:

- AI-based tension optimization

- Automated defect detection

- Predictive maintenance systems

- IoT connectivity for remote monitoring

- Smart production analytics

These innovations will further enhance productivity, reduce downtime, and allow factories to operate with greater precision and efficiency.

Selecting the appropriate machine depends on production goals, fabric type, and yarn specifications. Key considerations include:

- Required fabric width

- Desired gauge range

- Production volume targets

- Yarn characteristics

- Factory space availability

Manufacturers should evaluate both current and future needs when choosing equipment to ensure long-term operational flexibility.

The Interlock Open Width Circular Knitting Machine represents a significant advancement in textile manufacturing technology, combining precision engineering, automation, and versatile production capabilities. By merging interlock knitting performance with open-width fabric output, it eliminates common challenges such as central creases, uneven tension, and excessive waste.

With adjustable diameters, gauge ranges, and feeder configurations, these machines provide exceptional flexibility for producing a wide variety of textiles—from everyday apparel to high-performance technical fabrics. Their high production capacity, intelligent safety systems, and automated fabric handling make them ideal for modern factories seeking efficiency, consistency, and scalability.

As the textile industry continues to embrace automation, sustainability, and high-quality standards, interlock open width circular knitting machines are poised to play a vital role in shaping the next generation of fabric manufacturing. For producers aiming to enhance productivity while maintaining premium fabric quality, this technology offers a powerful and future-ready solution.

Previous: How the Three Thread Fleece Circular Knitting Machine Enhances Textile Manufacturing

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.