How the Three Thread Fleece Circular Knitting Machine Enhances Textile Manufacturing

Feb 10, 2026

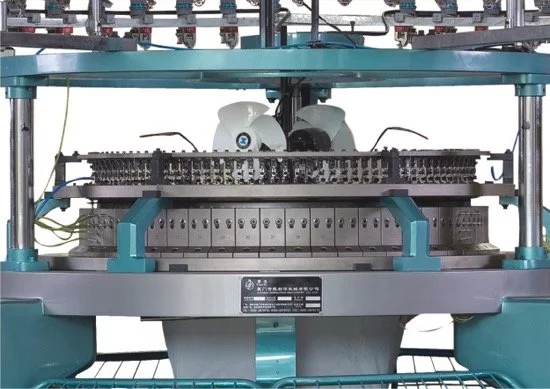

In the world of textile manufacturing, efficiency, versatility, and consistent product quality are critical factors in achieving competitive success. The Three Thread Fleece Circular Knitting Machine, designed to meet these demands, has become an essential tool for manufacturers aiming to produce high-quality fleece fabrics. Whether used for outerwear, home textiles, or sportswear, this machine is revolutionizing the fleece production process with its ability to create soft, durable, and warm fabrics. This article delves into the key features, benefits, applications, types, and operation of the Three Thread Fleece Circular Knitting Machine, highlighting its importance to modern textile manufacturing.

The Three Thread Fleece Circular Knitting Machine offers several unique features that set it apart from traditional knitting machines, making it a powerful tool for textile manufacturers.

One of the standout features of the Three Thread Fleece Circular Knitting Machine is its advanced automatic yarn tension control system. This technology ensures that each yarn is fed into the machine at the perfect tension, resulting in a fabric with consistent thickness and smoothness. This is particularly important for fleece fabrics, where uneven tension can lead to defects like puckering or inconsistent loops, ultimately compromising the quality of the final product. The automatic tension control helps prevent these issues, producing a flawless fabric every time.

The machine's ability to handle three separate threads allows manufacturers to create a wide range of fleece textures and patterns, from soft, fluffy fabrics to dense, insulated materials. This versatility gives manufacturers the flexibility to meet varying market demands, offering different types of fleece for outerwear, activewear, home textiles, and more. The machine can produce fabrics with distinct textures on both sides, providing an opportunity to create double-faced fleece materials for enhanced functionality.

Unlike many traditional knitting machines that are bulky and take up considerable space, the Three Thread Fleece Circular Knitting Machine is designed to be compact and space-efficient. This makes it suitable for a wide variety of factory sizes, from large production facilities to smaller-scale operations. Manufacturers can install multiple machines in a small space, optimizing their factory floor layout while maximizing production capacity.

The machine's user-friendly interface ensures that even operators with minimal training can efficiently run the machine. The intuitive controls allow for quick adjustments to parameters such as yarn tension, stitch type, and pattern design. Moreover, the Three Thread Fleece Circular Knitting Machine is built to be low-maintenance, reducing downtime and service costs. With automated functions and durable components, the machine requires minimal intervention, allowing operators to focus on production rather than constant machine upkeep.

With rising energy costs, many manufacturers are seeking ways to reduce operational expenses without compromising production quality. The Three Thread Fleece Circular Knitting Machine is engineered with energy efficiency in mind. Its advanced motors and optimized knitting processes ensure that fabric is produced at high speeds while consuming less electricity. This energy-efficient design not only lowers operational costs but also supports manufacturers in their sustainability efforts.

The Three Thread Fleece Circular Knitting Machine provides several key advantages for textile manufacturers looking to stay competitive in a fast-paced market:

Time is money in the manufacturing world, and the Three Thread Fleece Circular Knitting Machine significantly improves production speed compared to traditional knitting machines. The high-speed knitting process ensures that larger volumes of fabric can be produced in a shorter amount of time, meeting the demands of high-volume orders. This increase in production capacity is crucial for manufacturers looking to scale their operations and fulfill bulk orders.

Thanks to its automated yarn tension control and advanced knitting technology, the Three Thread Fleece Circular Knitting Machine ensures that every piece of fabric is produced with uniform consistency. The machine maintains precise stitch patterns, preventing defects and inconsistencies that could result in fabric rejections or returns. The consistency in quality is essential for building brand reputation and retaining customer trust in the long term.

The ability to adjust the fabric's texture and design is one of the most significant benefits of the Three Thread Fleece Circular Knitting Machine. By varying the yarn feeds and stitch patterns, manufacturers can produce fleece fabrics with different textures, from smooth and soft to thick and textured. This ability to customize fabric design allows manufacturers to offer a wider variety of products that cater to diverse consumer preferences, ensuring that they stay ahead of trends and market demands.

Manufacturers are always looking for ways to lower production costs without sacrificing quality, and the Three Thread Fleece Circular Knitting Machine delivers on this front. With its high efficiency, low maintenance requirements, and energy-saving features, the machine reduces operating costs over time. Additionally, its fast production speed means that manufacturers can produce more units in less time, increasing their profitability.

In today's world, sustainability is more important than ever. The Three Thread Fleece Circular Knitting Machine plays a part in reducing a manufacturer's carbon footprint. Its energy-efficient design minimizes electricity usage, while its ability to produce high-quality fleece fabrics means less waste in the form of defective materials. Manufacturers can further enhance their sustainability efforts by using eco-friendly yarns and dyes in combination with the machine.

The Three Thread Fleece Circular Knitting Machine is incredibly versatile and can be used to produce a wide range of fleece fabrics for various industries. Below are the primary applications of the machine:

The most common application of fleece fabrics is in the production of outerwear and winter apparel. Fleece jackets, hoodies, sweaters, and vests are all highly popular items, especially in colder climates. Fleece is favored for its warmth, lightness, and moisture-wicking properties, making it ideal for activewear and outdoor clothing. The Three Thread Fleece Circular Knitting Machine allows manufacturers to create fleece fabrics with the perfect balance of softness, insulation, and durability for high-performance winter garments.

Fleece fabrics are also widely used in home textiles, including blankets, throws, pillow covers, and bedding. The machine's ability to produce soft and fluffy fleece makes it perfect for creating cozy home products. Manufacturers can create fabrics in various textures and colors, giving consumers a wide range of options for their homes. With the increasing demand for comfort-driven home goods, the Three Thread Fleece Circular Knitting Machine helps manufacturers stay competitive in the home textiles market.

Sportswear and activewear are other significant markets for fleece fabrics. The breathable, lightweight, and insulating properties of fleece make it a popular choice for sweatshirts, leggings, and outer layers in sports and fitness clothing. The Three Thread Fleece Circular Knitting Machine can produce fabrics that provide comfort and flexibility, ensuring that athletes and fitness enthusiasts can perform at their best in cold weather conditions.

Apart from general applications, the Three Thread Fleece Circular Knitting Machine can be used to produce specialty fleece products like gloves, hats, scarves, and even upholstery fabrics. These products require fleece materials with specific characteristics such as warmth, softness, and durability, which the machine can easily produce. By offering customized fleece options, manufacturers can expand their product offerings and reach niche markets.

The Three Thread Fleece Circular Knitting Machine comes in different types, each tailored to produce a specific kind of fleece fabric. Here are the most common types:

The Single Jersey Fleece Knitting Machine is designed to create a single-layer fleece fabric with a loop-back effect. This type of fleece fabric is soft and lightweight, making it ideal for creating garments like lightweight jackets and casualwear. The machine produces a smooth and comfortable fabric that retains warmth while remaining breathable, making it a popular choice for everyday clothing.

The Rib Fleece Knitting Machine produces ribbed fleece fabric with a double-sided loop-back effect. This ribbed texture adds extra warmth and durability to the fabric, making it a perfect choice for heavier outerwear like sweaters, sweatshirts, and cardigans. Ribbed fleece has a distinctive texture that is visually appealing and highly functional for cold weather apparel.

The Interlock Fleece Knitting Machine is used to create interlock fleece fabric, which is known for its stable structure and durability. The interlock knitting technique results in a fabric with a smooth surface on both sides, offering enhanced strength and resistance to wear and tear. This type of fleece is ideal for producing high-performance garments, including sportswear and activewear.

The Three Thread Fleece Circular Knitting Machine operates on a circular knitting system. Yarns are fed into the machine, where they are knitted in a continuous tube. This tube of fabric can then be cut to the desired length or processed further with treatments like dyeing or finishing. The three-thread system allows for the creation of unique textures, making the fabric suitable for various applications. The machine's advanced computer control system ensures precision and efficiency, offering operators the ability to make quick adjustments to parameters like stitch type and yarn tension.

The Three Thread Fleece Circular Knitting Machine represents a breakthrough in textile manufacturing, offering enhanced efficiency, fabric quality, and versatility. Its advanced features, such as automatic yarn tension control, energy efficiency, and user-friendly operation, make it an invaluable asset for textile manufacturers. Whether used for producing outerwear, home textiles, or activewear, the Three Thread Fleece Circular Knitting Machine helps manufacturers meet market demands while keeping costs in check. With its ability to produce high-quality fleece fabrics at scale, this machine is set to remain a key player in the textile industry for years to come.

Previous: Interlock Open Width Circular Knitting Machines Drive Efficiency and Fabric Quality

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.