Single Jersey Open-width Computerized Jacquard Circular Knitting Machine

Aug 25, 2025

In today’s textile industry, efficiency, flexibility, and innovation are the driving forces behind progress. Among the latest advancements, the Single Jersey Open-width Computerized Jacquard Circular Knitting Machine has emerged as a powerful solution for fabric manufacturers worldwide. Built on the foundation of the traditional single jersey circular knitting machine, this upgraded system integrates jacquard knitting technology with an open-width slitting function, creating fabrics with greater diversity, precision, and usability.

Unlike conventional knitting machines that produce tubular fabrics, this model offers the ability to knit fabrics directly into open-width form. This unique function ensures smoother production, eliminates center creases, and allows fabrics to be ready for immediate rolling or processing. In addition, its advanced computerized control system enables designers and manufacturers to produce complex jacquard patterns with speed and accuracy, meeting the growing demand for customized and fashion-forward textiles.

As the fashion industry, home textile markets, and technical fabric sectors continue to expand, the need for versatile knitting machines is greater than ever. The Single Jersey Open-width Computerized Jacquard Circular Knitting Machine is designed to address these needs—offering enhanced patterning flexibility, improved durability, and streamlined production for a wide variety of fabric applications.

One of the standout features of this knitting machine is its advanced computer system, which controls the needle selection on the cylinder with unmatched flexibility. Designers can easily load patterns through user-friendly software, eliminating the need for complex manual programming. Normal drawing software is fully compatible, making it simple for textile engineers to create new jacquard designs without additional technical barriers.

The machine supports multiple knitting techniques, including:

3-way selection: loop / tuck / float

4-way selection: loop / float / tuck / transfer

5-way selection: loop / float / tuck / transfer with enhanced options

This broad range of needle selection methods enables the creation of highly intricate patterns, textures, and fabric structures in record time. Complex organizational structures of fabrics—such as geometric jacquards, multi-color motifs, or textured designs—can be executed with precision and consistency.

Furthermore, the machine is equipped with USB storage, allowing thousands of patterns to be saved and recalled instantly. This not only enhances productivity but also provides flexibility for manufacturers serving multiple clients with diverse requirements.

The fabrics produced by the Single Jersey Open-width Computerized Jacquard Circular Knitting Machine are incredibly versatile, catering to both fashion and functional applications. Its ability to generate three-dimensional jacquard patterns with multiple colors makes it especially valuable for modern apparel and home textiles.

Some key applications include:

Fashion Apparel: sweaters, T-shirts, polo shirts, gym wear, sportswear, yoga suits, swimwear, tights, and underwear.

Home Textiles: towels, flannel, arctic velvet, coral velvet, PV velvet, and carpets.

Technical Textiles: fabrics for automotive seat cushions, industrial covers, and specialty garments.

Specialty Fabrics: mesh jacquards, pique, elastane plating, and other stretch or breathable fabrics.

The inclusion of a Lycra feeder expands the machine’s capabilities further, enabling the production of highly elastic fabrics such as swimwear and performance sportswear. This makes the machine an indispensable tool for textile factories aiming to diversify their product lines and meet the demands of global fashion trends.

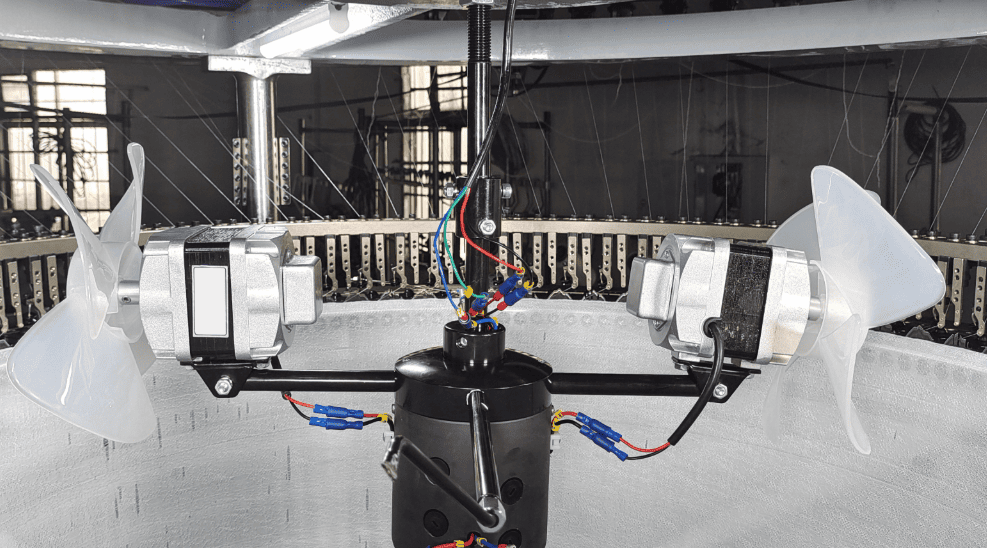

The Single Jersey Open-width Computerized Jacquard Circular Knitting Machine is designed with long-term durability, precision, and user convenience in mind. Each component is carefully engineered to maximize performance while reducing operational challenges. Below are its standout features:

Cam system designed for high-speed operation minimizes needle wear and tear.

Archimedes-precision stitch adjustment ensures accuracy in every production cycle.

Equipped with HEALY-brand ball bearings (imported from England) for smooth performance and stability.

High wear resistance and noiseless design improve working conditions on the factory floor.

Zirconium Ceramic Yarn Guides ensure that each yarn is handled carefully, maintaining fabric quality and minimizing yarn wastage.

Oil-immersed gears guarantee long-term durability, reducing maintenance frequency.

Components are manufactured using strict high-standard materials and advanced heat treatment for maximum efficiency.

Central stitch adjustment makes fabric density control accurate and hassle-free.

Scale markings allow operators to record settings, ensuring consistent results across multiple machines.

Adjustable spreader helps control fabric inclination, making rolling and folding simple.

Synchronous rolling and folding system ensures even fabric tension, preventing water ripples or uneven textures.

Forward cone cloth pusher avoids reverse insertions and keeps cloth edges flat, reducing yarn consumption.

Outer sleeve rolling rod design makes fabric removal quick and efficient.

Induction switch device automatically stops the machine if the cloth is not fully cut, preventing fabric loss and machine damage—especially effective when working with elastic fabrics.

The integrated open-width take-up unit is a defining feature of this machine, designed to slit, open, and roll fabric directly after knitting. By doing so, it prevents center creases and ensures fabrics are smooth, ready for processing, or immediate packaging.

Key advantages include:

No folding marks – The fabric is slit and rolled directly without folding, preserving a smooth finish.

Automatic shutdown – When the cutting process is incomplete, the induction device halts the machine to prevent waste.

Flexible sizing – The rolling stick accommodates fabrics of various widths, even smaller dimensions.

Consistent tension control – Roller speed adjustment maintains even fabric tightness, ensuring high-quality output.

Simple operation – The extension system is easy to set, saving time during production.

No gear marks – Since no gears are included in the system, fabric surfaces remain flawless.

Extended needle life – Proper tension management reduces stress on needles, prolonging their usability.

This open-width system directly improves return on investment (ROI) by reducing fabric waste, enhancing quality, and minimizing downtime.

Today’s textile market is driven by speed, customization, and quality. Consumers are increasingly looking for fabrics with unique textures, colors, and performance features. The Single Jersey Open-width Computerized Jacquard Circular Knitting Machine is perfectly suited for this environment.

By enabling quick pattern changes, efficient handling of elastic yarns, and flawless fabric rolling, the machine empowers textile manufacturers to stay ahead of fashion cycles and industry demands. Whether producing high-end fashion garments, durable sportswear, or luxury home textiles, this machine delivers the flexibility required to remain competitive.

Moreover, every machine is built with a focus on humanized design, ensuring operators can work efficiently and comfortably. Easy operation reduces training requirements, while reliable safety features protect both the equipment and the product.

As sustainability becomes a priority, textile machinery must evolve to reduce waste, save energy, and extend product life cycles. The Single Jersey Open-width Computerized Jacquard Circular Knitting Machine supports these goals in several ways:

Waste Reduction: Crease-free, open-width fabrics minimize the need for reprocessing.

Durability: High-quality components reduce machine breakdowns and extend lifespan.

Energy Efficiency: Smooth operation and advanced yarn management optimize resource use.

Eco-Friendly Fabrics: Compatibility with organic cotton, bamboo fibers, and recycled yarns supports green textile production.

Looking ahead, the integration of AI-driven predictive maintenance, IoT connectivity, and real-time production monitoring could further enhance this machine’s role in sustainable textile manufacturing.

The Single Jersey Open-width Computerized Jacquard Circular Knitting Machine represents a leap forward in textile machinery. It combines the traditional strengths of single jersey knitting with modern jacquard technology and innovative open-width fabric handling. From versatile fabric applications to improved production efficiency, it provides manufacturers with the tools they need to excel in today’s competitive textile industry.

With its long service life, precision engineering, and capacity for producing high-quality fabrics, this machine is more than just equipment—it is an investment in the future of textile production. By choosing this advanced knitting solution, manufacturers can ensure they meet the demands of fashion trends, technical textiles, and consumer expectations while achieving greater efficiency and profitability.

Next: Double Side Jacquard Circular Knitting Machine for Syrian Market

Previous: Double Jersey Dial and Cylinder Circular Knitting Machine Ready for the Indonesian Market

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.