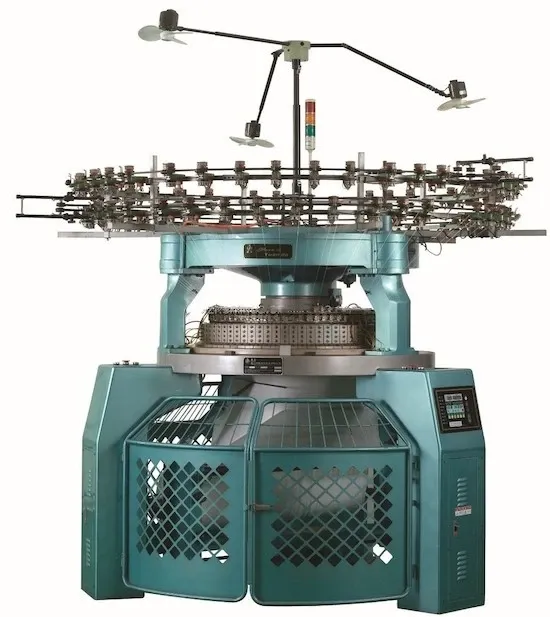

Double Jersey Waffle Check Knitting Machine for Indonesia Market

Apr 16, 2025

As Indonesia’s textile and garment sector continues to expand with increased demand for versatile, high-quality knit fabrics, machinery manufacturers are stepping up to provide cutting-edge solutions tailored to local production needs. One such innovation making waves across the Indonesian knitting landscape is the Double Jersey Waffle Check Fabrics Circular Knitting Machine — a powerhouse of flexibility, efficiency, and fabric precision.

Indonesia, known for its robust textile exports and growing domestic fashion industry, has seen a surge in demand for high-performance circular knitting machines capable of producing more complex and structured knit fabrics. From men’s and women’s fashion to technical textiles and healthwear, manufacturers are seeking equipment that offers both quality and adaptability. The Double Jersey Waffle Check Circular Knitting Machine is designed to answer exactly that call.

With its advanced mechanical configuration and ability to handle a wide range of fabrics, this machine is perfectly suited for producers aiming to meet domestic and international demand for premium interlock and waffle-patterned fabrics.

The machine is offered in a range of configurations to suit various production requirements:

Diameter: 8 to 44 inches

Gauge: 6 to 40 Gauge

Number of Feeders: 16 to 88/106 feeders

This wide range of customization allows textile mills to tailor the machine to the specific needs of their production lines, optimizing output without compromising fabric quality.

One of the major strengths of the Double Jersey Waffle Check Circular Knitting Machine lies in its remarkable versatility. It can produce an extensive range of double jersey fabrics, including:

Waffle check fabrics

Interlock fabrics

Elastic health cloth

Twill

Air layer

Double mesh

Premium apparel fabrics for both men's and women's fashion

This flexibility makes it an ideal investment for Indonesian manufacturers targeting multiple market segments — from local garment brands to large-scale international buyers.

At the heart of this machine’s performance are several well-engineered features:

Closed-track cam system: Both upper and lower dials utilize a closed-track cam design. The cams are capable of performing knit, tuck, and miss functions, enabling intricate fabric designs and consistent pattern control.

Independent yarn feeders: Each feeder can be adjusted independently, granting greater control and enabling multi-color, multi-texture production.

Lycra attachment capability: An additional Lycra attachment allows the machine to knit elastic double jersey fibers, ideal for healthwear and stretch fabrics.

Interchangeable system: This model is easily convertible into a rib knitting machine, offering enhanced production flexibility without requiring additional machinery.

These features collectively contribute to a stable and smooth knitting experience, minimizing downtime and increasing operational efficiency — two crucial factors in Indonesia’s competitive textile environment.

What sets this machine apart in the Indonesian market is its sturdy structure and reliable performance even under high-speed operations. It’s built with durability in mind, using premium-grade materials for critical components and maintaining precise synchronization between cam systems and yarn feeders.

Its modular design also makes it easier to maintain and upgrade. For textile mills operating in areas with high humidity or challenging power conditions, this machine’s reliability ensures uninterrupted operation and lower maintenance costs over time.

The waffle check fabric market is gaining traction in Indonesia due to its unique structure, texture, and visual appeal. These fabrics are often used in:

Premium casualwear

Activewear

Health and wellness apparel

Children's clothing

Undergarments

Thanks to the machine’s precise cam control and ability to handle Lycra and elastic blends, manufacturers can now efficiently produce waffle-patterned fabrics with consistent structure, excellent stretch recovery, and superior softness — all characteristics in demand among today’s discerning consumers.

As the Indonesian government continues to push forward its “Making Indonesia 4.0” roadmap, which aims to modernize the country’s manufacturing industry, innovations like the Double Jersey Waffle Check Circular Knitting Machine align perfectly with this initiative.

By integrating such advanced textile machinery, local producers can:

Increase production efficiency

Diversify product offerings

Improve product quality for export

Strengthen local supply chains

Create jobs in textile-heavy regions such as Bandung, Semarang, and Surabaya

Several Indonesian manufacturers have already integrated this model into their production lines with impressive results. A garment factory in Bandung reported a 30% increase in output after switching to this machine, alongside a marked improvement in fabric uniformity. Another knitwear producer in Central Java praised the machine's ability to handle both basic and high-end fabric orders, allowing them to expand into new markets.

Feedback from factory operators also emphasizes the ease of use and smooth maintenance routines — critical for manufacturers facing labor shortages or training challenges.

Suppliers of the Double Jersey Waffle Check Circular Knitting Machine offer comprehensive support for Indonesian buyers, including:

On-site installation and training

Spare parts availability

Custom machine configurations for specific fabrics

Technical consultation for setting up multi-fabric production workflows

This level of service ensures that buyers are not just purchasing a machine — they’re gaining a long-term production partner.

As ASEAN’s second-largest textile exporter after Vietnam, Indonesia is strategically positioned to benefit from regional trade agreements and growing demand in Southeast Asia. With a machine like this, manufacturers can scale up and capture more of the mid- to high-end fashion fabric market across neighboring countries like Malaysia, Thailand, and the Philippines.

Waffle check fabrics are particularly in demand among fashion-forward urban markets where texture and comfort are highly valued — giving Indonesian producers an edge in these niches.

The Double Jersey Waffle Check Fabrics Circular Knitting Machine stands out as a robust, efficient, and versatile solution tailored to the evolving needs of Indonesia’s dynamic textile sector. Whether used for basic interlock production or sophisticated fashion fabric runs, this machine offers the quality, adaptability, and efficiency required to succeed in both domestic and export markets.

For forward-thinking manufacturers in Indonesia looking to upgrade their knitting capabilities and stay ahead of the curve, this machine represents a smart, strategic investment in long-term success.

Next: How to Easily Change Patterns on a Double Jersey Computerized Jacquard Knitting Machine

Previous: Double-Sided Interlock Knitting Machine Enters Peru's Textile Market

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.